Aluminum Raw Material

Aluminum is emerging as a top choice in the packaging industry, but what’s driving this shift? Known for its durability and versatility, aluminum offers a unique combination of properties that make it increasingly attractive for a wide range of packaging needs. However, as with any material choice, there are advantages, challenges, and factors to consider. This guide will help you understand why aluminum is gaining popularity and if it’s the right fit for your products.

Aluminum’s popularity in packaging is due to its recyclability, lightweight, and high barrier properties, making it ideal for preserving product freshness. As sustainability becomes a focal point, aluminum packaging offers a circular solution, easily recycled without losing quality.

From environmental benefits to technical specifications, aluminum is redefining how products are packaged and perceived. But what’s the backstory of aluminum in the packaging sector, and what specific characteristics make it so suitable?

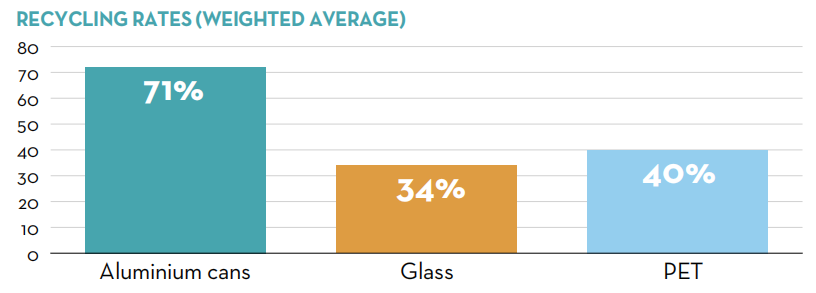

Aluminum packaging has been extensively researched and proven to be one of the most sustainable materials, with a recycling rate of over 70% globally.

Aluminum Recycling Rate

Aluminum cans are the most recycled packaging type globally, with an average recycling rate of 70%.True

As one of the most widely recycled forms of packaging, aluminum cans have an exceptionally high recycling rate worldwide. Their high value in recycling markets and well-established recycling systems make them a leader in sustainable packaging practices.

Aluminum cans are the most recycled packaging type globally, with an average recycling rate of 70%.False

Although aluminum cans are recycled widely, they are not necessarily the most recycled packaging type in every region. Other packaging materials like certain plastics or paper products may have higher recycling rates in some areas, depending on local recycling practices and infrastructure.

What Are the Key Characteristics of Aluminum?

Aluminum1 is known for a few critical properties that distinguish it from other materials. But what makes these characteristics especially valuable for packaging?

Aluminum is lightweight, strong, corrosion-resistant, and has high thermal conductivity, making it ideal for protecting contents from light, air, and moisture.

aluminum packaging

Aluminum’s high barrier protection is key for food and beverage industries, ensuring content quality over extended periods. Additionally, its flexibility in forming complex shapes without compromising strength provides unique branding options.

Aluminum can reflect 95% of light and is impermeable to oxygen, helping maintain the freshness of packaged goods.True

By reflecting nearly all light and preventing oxygen from entering the package, aluminum offers superior protection against light-sensitive and oxygen-sensitive products, which helps maintain flavor, color, and overall product quality during storage and transport.

How Has Aluminum Packaging Developed Over Time?

Introduction to History

The journey of aluminum packaging spans several decades, transforming from a niche solution to a mainstream choice. So, how did this material make its way to the forefront?

Aluminum packaging started with beverage cans in the mid-20th century, evolving to today’s multi-industry solutions due to improved recycling systems and sustainability demands.

From basic beverage cans to specialized pharmaceutical containers, aluminum packaging has evolved to meet the increasing demands of various industries. Environmental regulations and the need for longer shelf lives have driven this transformation.

Aluminum’s ability to be recycled without losing quality has supported its increased adoption in sustainable packaging.True

Unlike many materials that degrade with each recycling cycle, aluminum retains its properties, allowing it to be reused repeatedly without quality loss. This property is a key driver for sustainable packaging as brands and manufacturers seek materials with high reusability.

Why Is Aluminum Packaging Gaining Popularity in Recent Years?

Aluminum packaging has seen a surge in recent years, but what factors are propelling this growth?

The popularity of aluminum is largely due to its sustainability and consumer preference for recyclable, eco-friendly packaging.2

aluminum recyclable

Today’s environmentally conscious consumers are favoring products in recyclable and sustainable packaging. For brands, aluminum offers a way to market their products as eco-friendly. Moreover, its lightweight property helps reduce transportation emissions, supporting corporate sustainability goals.

Aluminum is infinitely recyclable, with nearly 75% of all aluminum ever produced still in use today.True

Aluminum's recycling efficiency allows nearly all of it to re-enter the production cycle. Its durability and reusability mean that a significant portion of the aluminum produced decades ago remains in circulation, underscoring its potential for sustainable manufacturing.

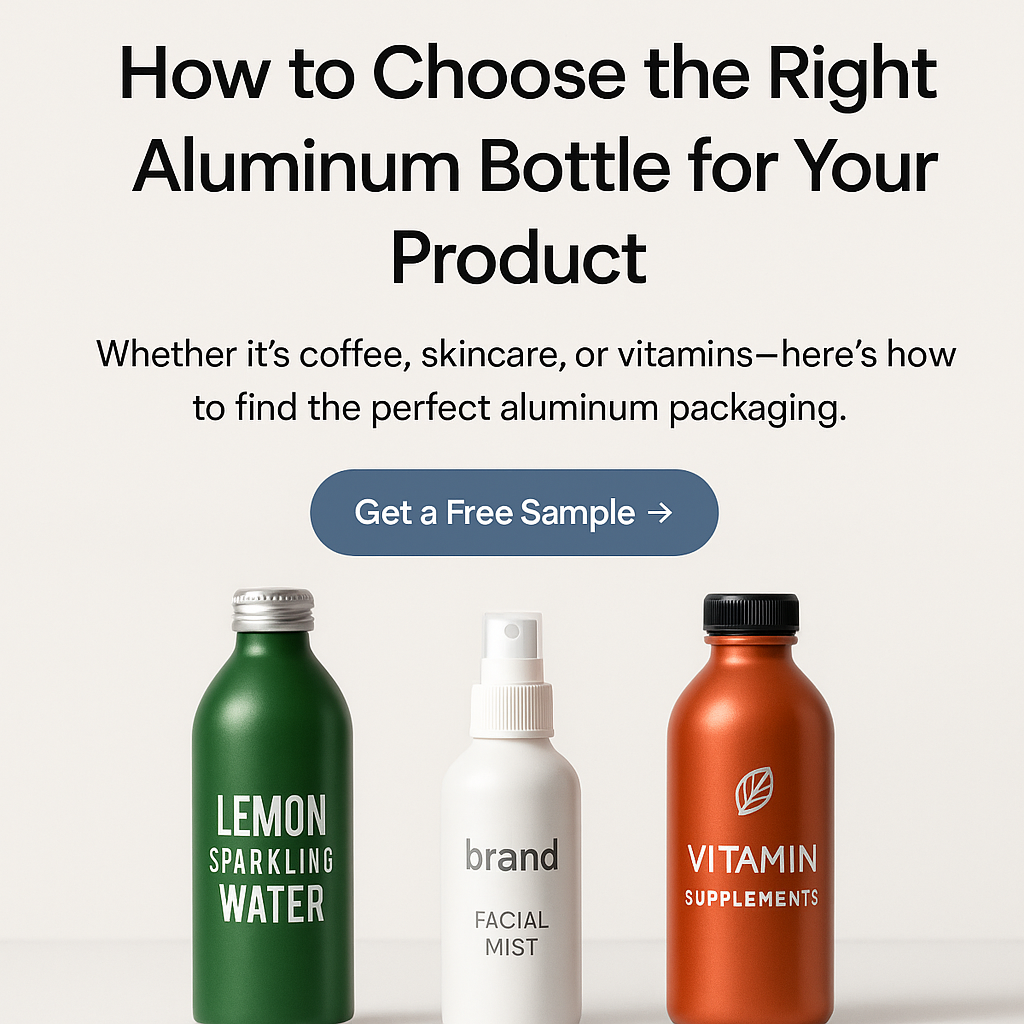

What Are the Common Types of Aluminum Packaging?

Introduction to Types of Aluminum Packaging

Aluminum packaging appears in several forms, each serving unique functions. But which types are most common, and why?

Aluminum packaging includes cans, bottles, trays, tubes, and foils, each offering versatility and protection for specific product categories.

Aluminum Packaging

The most common aluminum packaging types range from beverage cans and food trays to more specialized forms like pharmaceutical tubes and personal care bottles. Each type capitalizes on aluminum’s protective and preservative properties.

What Are the Pros and Cons of Aluminum Packaging?

Aluminum Bottle's advantage

Aluminum packaging comes with both benefits and limitations. But how do these pros and cons balance out for your business needs?

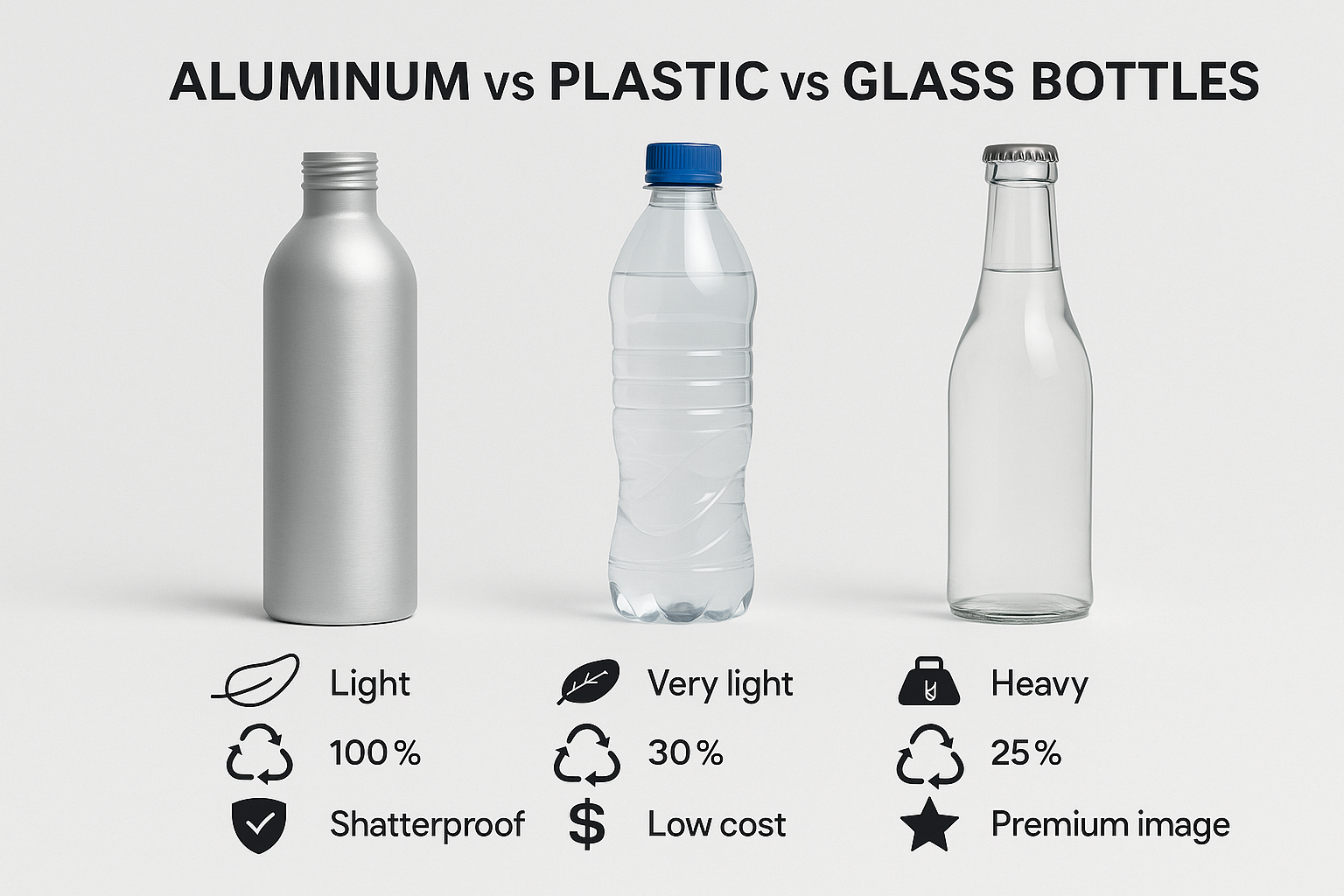

Aluminum is highly sustainable and offers excellent protection, but it can have a higher initial cost and requires energy-intensive production.

Advantages and Disadvantages of Aluminum Packaging

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Sustainability | Highly sustainable due to its infinite recyclability; uses less raw material over long term cycles | Production requires significant energy; can be more impactful than other materials initially |

| Barrier Properties | Excellent protection from light, air, and moisture, preserving product quality | Not suitable for all types of products (e.g., very acidic contents may react without lining) |

| Weight | Lightweight, reducing transportation costs and emissions | Lightweight, but may dent under certain conditions |

| Durability | Corrosion-resistant and long-lasting; withstands rigorous conditions | Denting potential; needs protective design to avoid damage during transit |

| Cost | Cost-effective over time due to recyclability and high reuse rate | Higher initial cost compared to some alternatives |

| Aesthetics & Branding | Sleek, premium look; easy to customize with various finishes and shapes | Requires additional design considerations for branding due to reflective surface |

Though production is energy-intensive, aluminum's recyclability significantly offsets its environmental footprint over time.True

The initial energy needed for aluminum production is offset by its recyclability, which uses up to 95% less energy than primary production. This capacity for efficient reuse makes aluminum an environmentally favorable choice in the long term.

What Factors Should You Consider When Choosing Aluminum for Packaging?

Introduction to Key Considerations

Selecting aluminum packaging requires careful evaluation. So, what are the primary considerations to keep in mind?

Consider factors like the desired shelf life, brand image, environmental impact, and cost when choosing aluminum packaging.

- Product Compatibility: Ensure that aluminum is suited for your product type.

- Budget Constraints: Aluminum may be more costly than other materials.

- Recycling Systems: Strongly consider whether your target market has robust recycling facilities.

Aluminum’s recyclability adds value in markets with well-developed recycling infrastructure.True

In markets with strong recycling systems, aluminum’s infinite recyclability enhances its environmental value, allowing it to be reused effectively and supporting circular economy goals. This reinforces aluminum as an ideal material for regions focused on waste reduction and resource efficiency.

Conclusion

Aluminum packaging is shaping the future of sustainable and efficient product packaging. Its unique blend of protective, aesthetic, and eco-friendly properties is paving the way for a more circular economy. For manufacturers and procurement professionals, aluminum offers a high-value solution that aligns with both product needs and environmental goals. Explore options, weigh the pros and cons, and make an informed choice for your packaging needs.