What’s the Minimum Order Quantity (MOQ) for Printed Aluminum Bottles—And Why?

Introduction: MOQ Isn’t Just a Number—It Reflects Real Production Logic

If you're new to aluminum packaging, you might wonder why suppliers often require a minimum order quantity (MOQ)—especially when it comes to custom-printed bottles. Whether you’re launching a new product or scaling an existing line, understanding how MOQs work will help you plan more efficiently and avoid unexpected costs.

At CPI, we believe in transparent communication. Here’s a clear breakdown of why MOQs exist and how you can make the most of them.

1. What’s the Typical MOQ for Printed Aluminum Bottles?

For printed aluminum bottles, the standard MOQ usually ranges from 5,000 to 30,000 units per design, depending on:

- Bottle size and shape

- Printing method(silk screen, heat transfer printing,and offset printing so on )

- Surface finish (matte, glossy, metallic)

At CPI, we typically set our printed bottle MOQ at 10,000 pcs per SKU, while blank (unprinted) bottles can start from lower quantities.

2. Why Is the MOQ Higher for Printed Bottles?

There are three main reasons:

▪ Setup Costs for Printing

Preparing a print run involves plate-making, color calibration, and machine setup. These fixed costs are the same whether you print 5,000 or 100,000 bottles—so smaller runs make the cost per unit too high.

▪ Material Waste & Efficiency

Printing lines require a calibration phase that wastes several hundred bottles per color. To reduce waste and improve cost efficiency, printers usually run batches at scale.

▪ Automated Line Requirements

Offset and high-speed lines are designed for volume. Running small quantities interrupts efficiency and scheduling, and sometimes simply isn’t feasible.

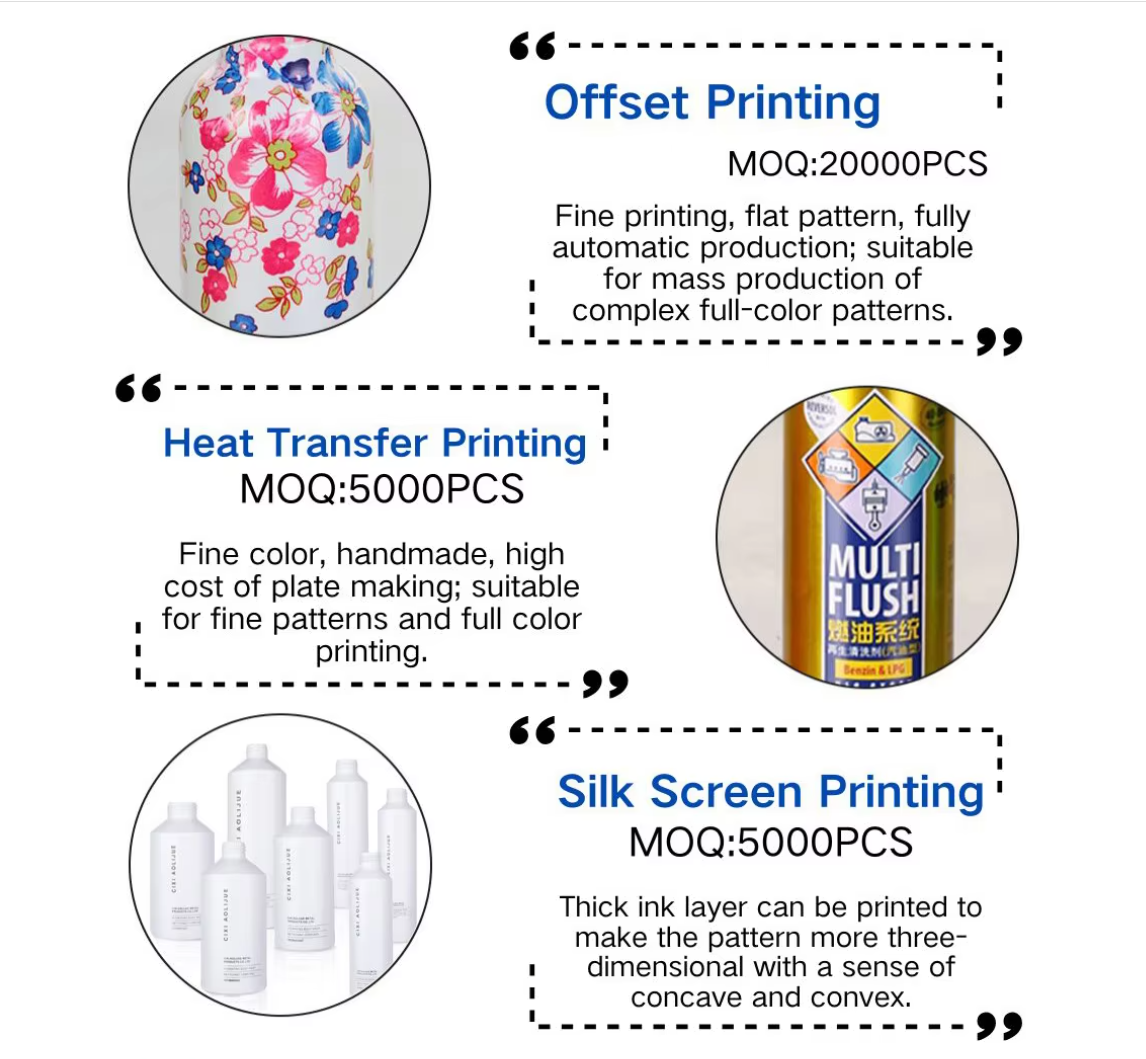

3. Does the MOQ Vary Based on the Printing Type?

Yes. MOQ depends heavily on the method:

| Printing Method | Typical MOQ | Notes |

|---|---|---|

| Screen Printing | 5,000–10,000 | Fewer colors, manual/semi-auto process |

| Offset Printing | 10,000–30,000 | Best for full-wrap multicolor prints |

| Heat Transfer Printing | 5,000-10,000 | Best for over 3 colors prints |

| Shrink Sleeve | 5,000–10,000 | Sleeve MOQ also affects final MOQ |

At CPI, we mainly offer screen, heat transfer and offset printing for best durability and visual quality.

4. Can You Start with a Smaller Trial Order?

Absolutely. If you’re launching a new SKU or doing market testing, we offer flexible solutions:

- Blank bottles with your label applied later

- MOQ exceptions on select items or print types

- Custom samples with mockup or small-batch printing (at additional cost)

Let us know your needs—we’ll find a way to support your growth.

5. Why Not Offer Low MOQs for All Clients?

It’s a balance between quality, efficiency, and cost. If we lowered MOQs too far:

- The cost per bottle would increase significantly

- The print quality might suffer on unsuitable equipment

- Lead times could become unpredictable

Instead, we focus on sustainable scale and consistent quality, especially for international clients who expect premium branding.

Conclusion: Plan Smart, Print Smart

Understanding MOQ isn’t a barrier—it’s a tool to help you plan realistically. At CPI, we’re always happy to explain, quote for different tiers, or help you build toward higher volumes.

👉 Ready to get started with a printed aluminum bottle? Contact us to get a custom quote and mockup preview.