When launching a new product line or testing a packaging concept, understanding the minimum order quantity (MOQ) for aluminum bottles is critical. MOQs can directly impact your budget, timeline, and go-to-market strategy.

Many first-time buyers wonder: Do I have to order 10,000 units to get started? Is there any flexibility?

Let’s explore what determines the MOQ, when flexibility is possible, and how you can move forward smartly—whether you’re testing or scaling.

Why do aluminum bottles have MOQs?

Aluminum bottles are typically produced in bulk using high-speed automatic lines or semi-production lines. Each custom run requires setup costs for:

- Printing or coating machines

- Mold alignment and cleaning

- Material consumption (aluminum slugs, internal lacquer, etc.)

Because of this, manufacturers set MOQs—usually starting around 5,000 to 30,000 units—to balance costs.

A lower quantity doesn’t always make the project easier; sometimes it raises per-unit prices and production inefficiencies.

Is it possible to order fewer bottles for testing?

Yes—if you're testing, doing a pilot launch, or building marketing samples, most manufacturers can accommodate with:

- ✅ Free samples: usually 5–10 pcs per model

- ✅ Paid test runs: 20–100 pcs (often from existing stock)

- ✅ Custom sample orders: 100–500 pcs via manual production

However, small-quantity orders may:

- Have limited customization (e.g. no custom printing)

- Use standard sizes and finishes

- Come with higher unit and shipping costs

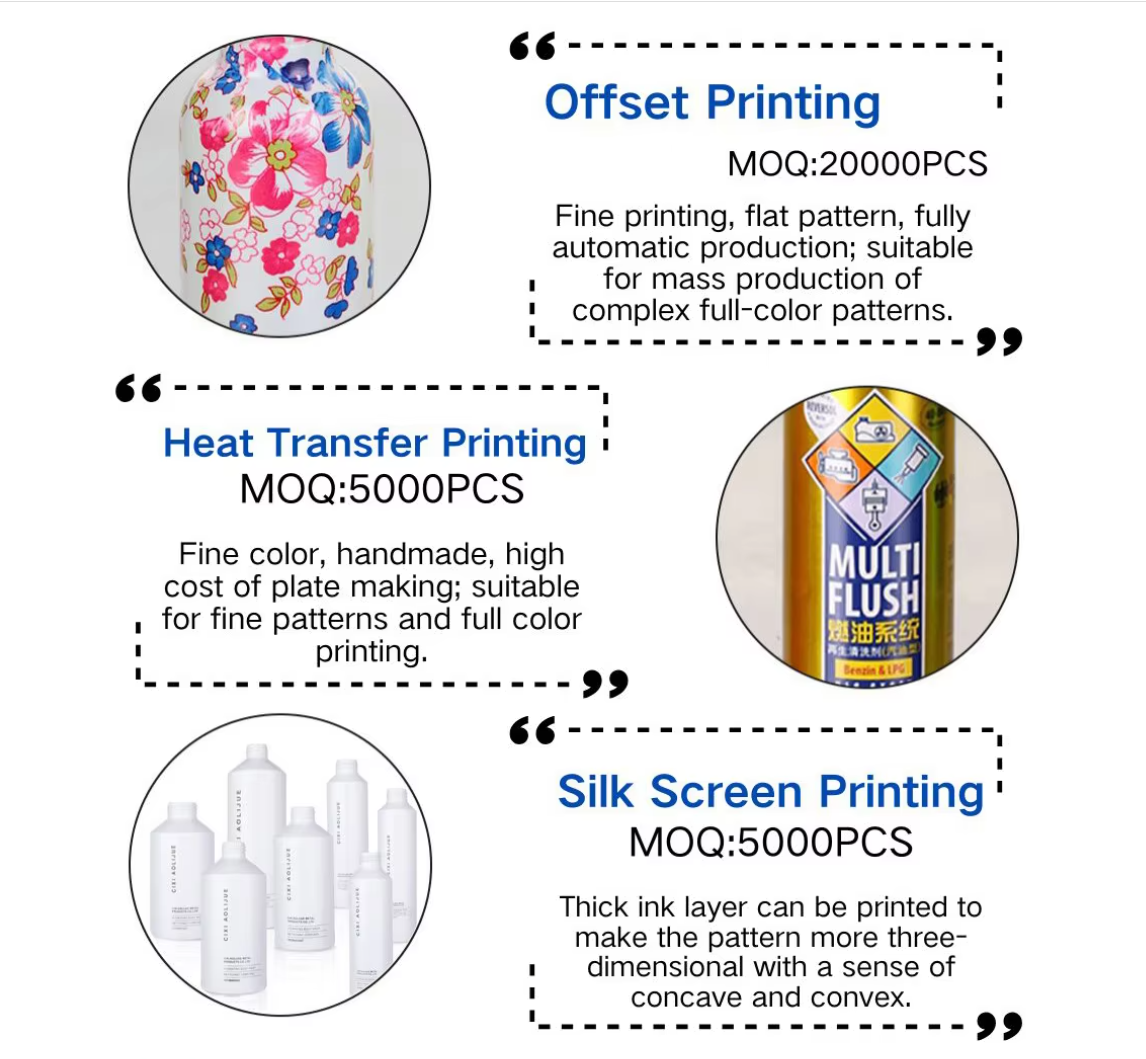

What’s the MOQ for custom printed aluminum bottles?

For custom-printed aluminum bottles, the MOQ generally ranges from:

- 3,000–5,000 pcs for silk screen printing

- 5,000–10,000 pcs for heat transfer or shrink sleeve printing

- 30,000 pcs+ for full custom molding or offset printing

Larger orders can unlock better pricing and full customization—including cap styles, shoulder shapes, and color matching.

How can you move forward if you’re not ready for a full MOQ?

If you’re not yet ready to commit to a full MOQ, here’s how you can still start:

- Request blank samples to test filling and compatibility

- Start with an MOQ-ready model (a popular size with existing tooling)

- Order plain bottles and add labels locally for early validation

- Combine your order with others (shared production line scheduling)

- Negotiate a step-by-step scale-up with your supplier

Conclusion

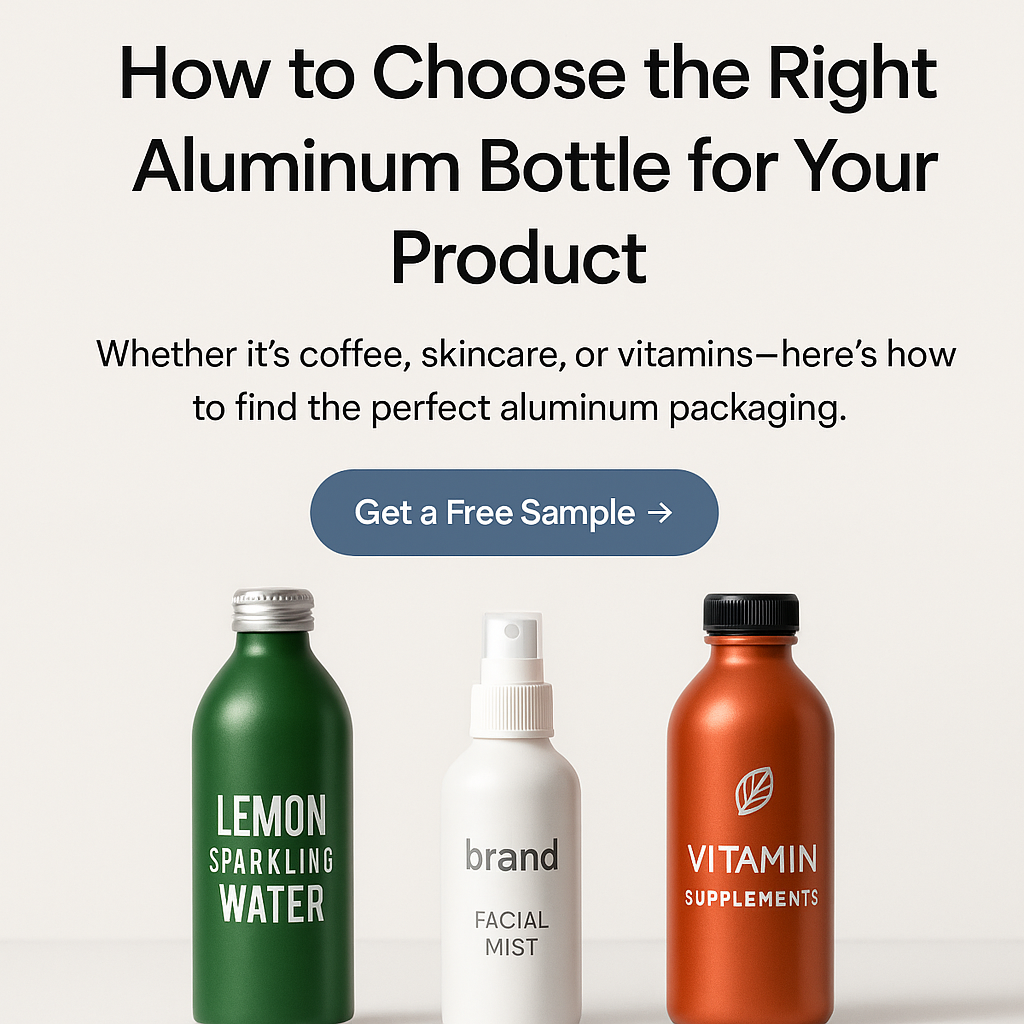

The MOQ for custom aluminum bottles may seem like a hurdle, but with the right strategy, it can be managed—even on a tight budget or early-stage launch. Many suppliers, including us at CPI, offer flexible testing support and stock samples to help brands move faster.

👉 Need fewer bottles for testing? Contact us to request free samples or a tailored MOQ plan.