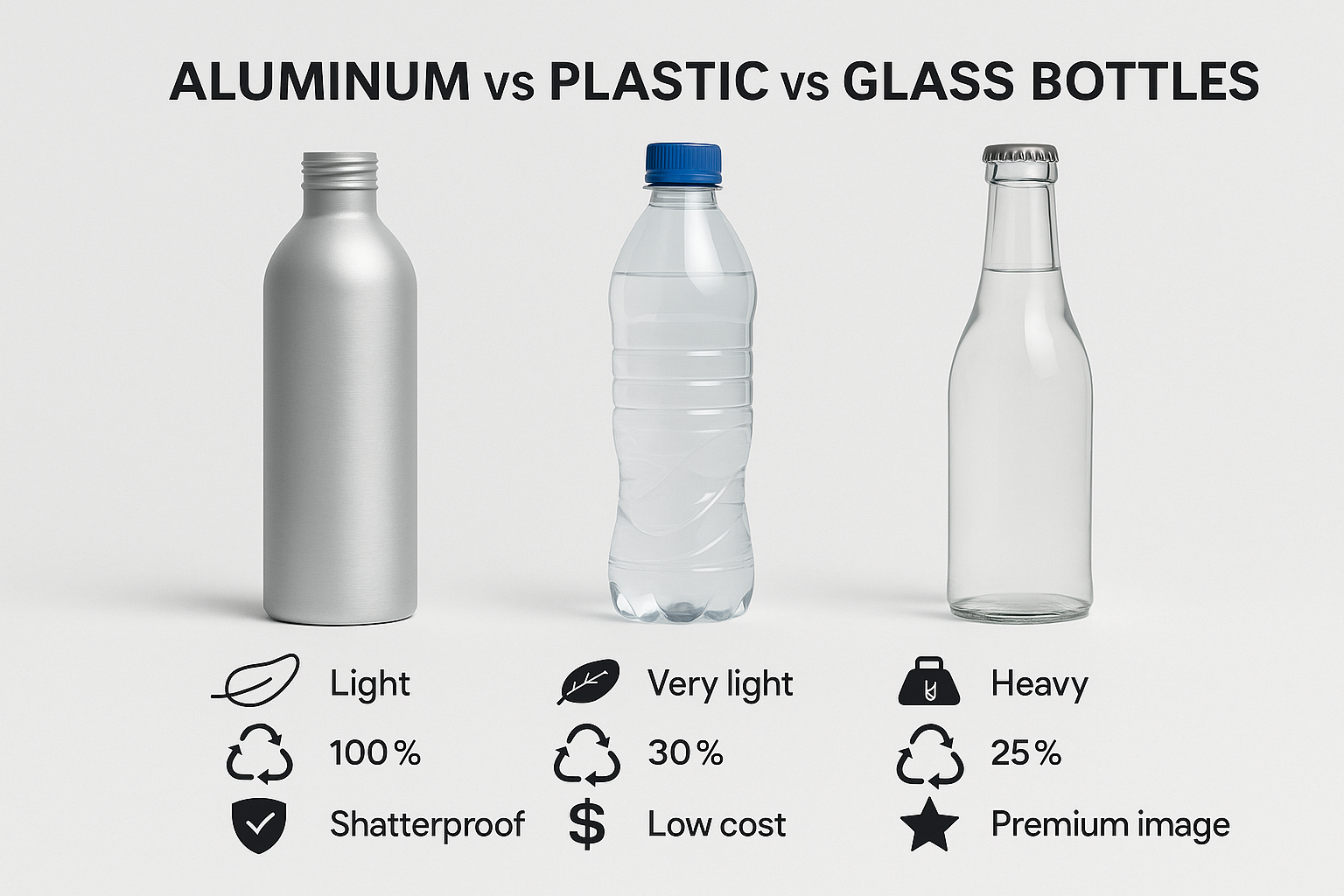

Aluminum bottles are lightweight, shatterproof, and infinitely recyclable, offering a balance of durability and sustainability. Plastic bottles are inexpensive but environmentally controversial, while glass bottles provide a premium feel but are heavier and more fragile. Choosing the right material depends on product type, branding goals, and logistics costs.

Table of Contents

Why Packaging Material Choice Matters for Your Brand

For B2B buyers, packaging is more than a container—it’s a sales driver, a brand storyteller, and often a sustainability statement. The right material choice can affect:

- Consumer perception of quality and eco-friendliness

- Total landed cost, including freight and handling

- Regulatory compliance in different markets

- Product safety during transport and storage

Overview of Aluminum, Plastic, and Glass Bottles

Aluminum Bottles

- Lightweight → lower freight costs

- Shatterproof → reduced breakage losses

- 100% recyclable without quality loss

- Ideal for beverages, cosmetics, pharmaceuticals, and personal care

Plastic Bottles

- Lowest cost to produce

- Very lightweight, but environmental impact is high

- Risk of product contamination if low-grade plastic is used

- Recyclability varies by region

Glass Bottles

- Premium look & feel → strong consumer perception in high-end markets

- Chemically inert → excellent product protection

- Heavy and fragile → higher freight and breakage costs

- High carbon footprint in production and transport

Side-by-Side Comparison Table

| Feature | Aluminum Bottles | Plastic Bottles | Glass Bottles |

|---|---|---|---|

| Weight | Light | Very light | Heavy |

| Durability | Shatterproof | Flexible | Breakable |

| Sustainability | 100% recyclable, high scrap value | Limited recycling rates | Recyclable but energy-intensive |

| Cost | Moderate | Low | High |

| Food/Cosmetic Safety | Excellent (BPA-free lining) | Varies | Excellent |

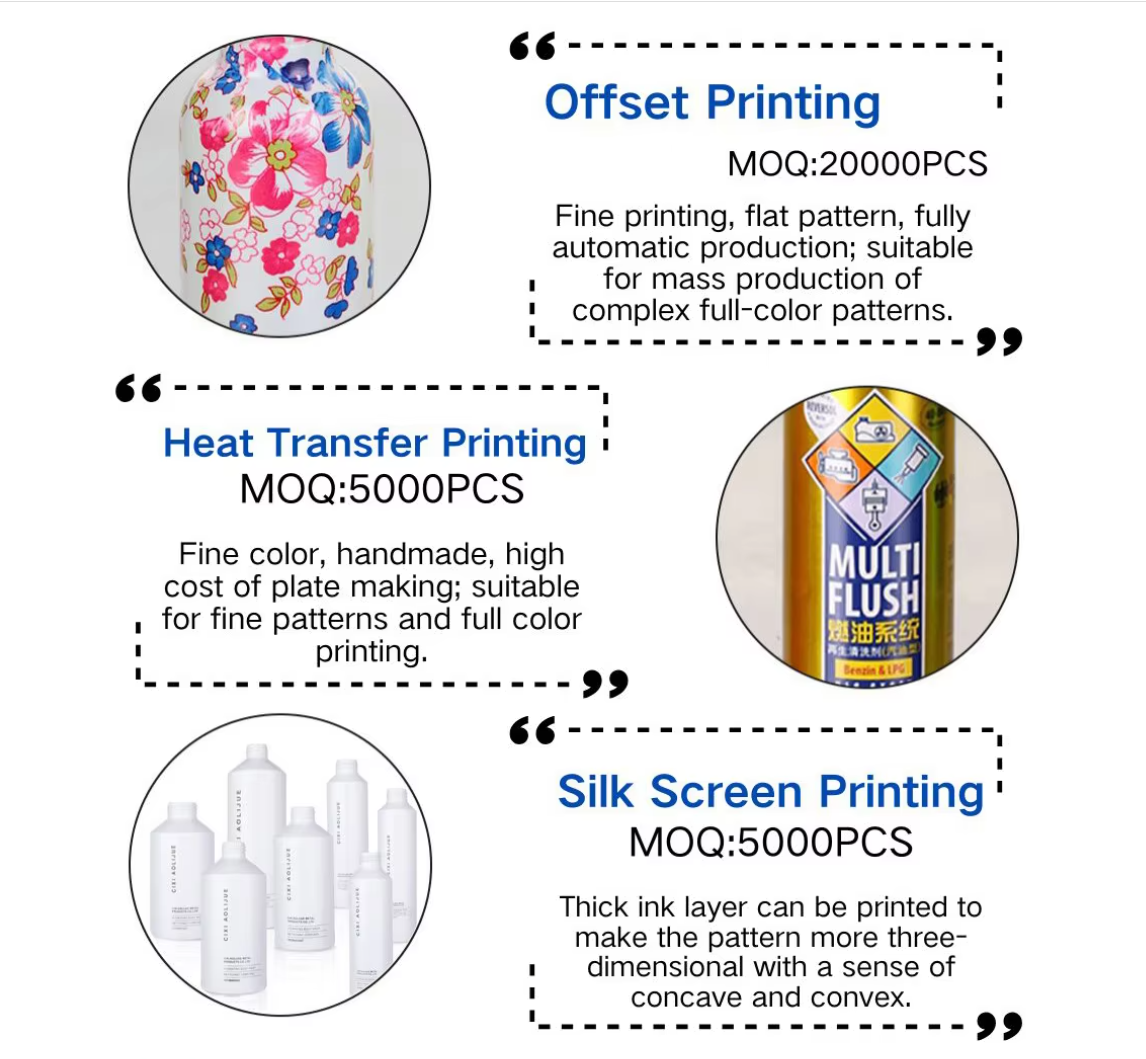

| Printing Options | Wide range, premium effects | Limited | Limited (labels) |

| Shipping Costs | Low | Lowest | Highest |

Performance and Brand Image

Aluminum bottles strike a rare balance between premium appeal and logistical efficiency.

- For mid- to high-end brands, aluminum provides a modern, sleek look without the fragility of glass.

- Plastic’s low cost appeals to mass-market segments but risks undermining brand sustainability claims.

- Glass still resonates in luxury segments, but transport challenges are a serious drawback for global supply chains.

Sustainability Impact

Aluminum is a leader in closed-loop recycling:

- Can be recycled infinitely without losing quality

- 75% of the aluminum ever produced is still in use today

- High scrap value motivates actual recycling vs. landfill

Plastic recycling rates are often below 10% in many markets, and glass—while recyclable—requires significant energy to process and transport.

Industry Applications

- Beverages: Water, juice, coffee, and energy drink brands moving from PET to aluminum for sustainability credentials.

- Cosmetics: Skincare and haircare lines replacing plastic with aluminum for premium positioning.

- Pharmaceuticals: Durable and light protection for sensitive formulations.

Conclusion & Next Steps

Choosing the right bottle material impacts more than your packaging line—it influences consumer trust, supply chain costs, and ESG performance.

At CPI, we help B2B buyers evaluate material options with real data on cost, durability, and sustainability.

📩 Contact us today for a free material suitability assessment for your product line.