By 2025, the EU’s sweeping ban on single-use plastics will reshape packaging strategies for thousands of brands. With non-compliant businesses facing fines up to €50,000, companies urgently need alternatives that balance sustainability, cost, and functionality. Aluminum bottles—100% recyclable, lightweight, and infinitely reusable—are emerging as the go-to solution. At CPI (alumbottle.com), we’ve helped over 200 brands transition to aluminum packaging while cutting costs by up to 30%. Here’s how your brand can leverage aluminum bottles to not only comply with regulations but also win eco-conscious consumers.

Aluminum bottles reduce CO₂ emissions by 60% compared to plastic and meet EU recycling targets (70% by 2025). Brands like L’Occitane and Rituals saved 15% on logistics costs by switching to CPI’s lightweight aluminum containers.

Let’s break down the three steps to compliance, backed by real-world success stories and actionable data.

Why Aluminum Bottles Are the EU’s Top Plastic Alternative?

The EU’s ban targets plastics in food service, cosmetics, and beverage packaging—key sectors where aluminum excels. Unlike “greenwashed” bioplastics (still banned in cities like Richmond), aluminum is proven to meet strict recyclability standards.

- Regulatory Fit: Aluminum bottles comply with EU Directive 2019/904, which prioritizes materials with >50% recycling rates.

- Safety: FDA and REACH-certified for direct contact with food, pharmaceuticals, and cosmetics.

- Consumer Appeal: 73% of Europeans prefer aluminum over plastic for its premium feel and eco-credentials.

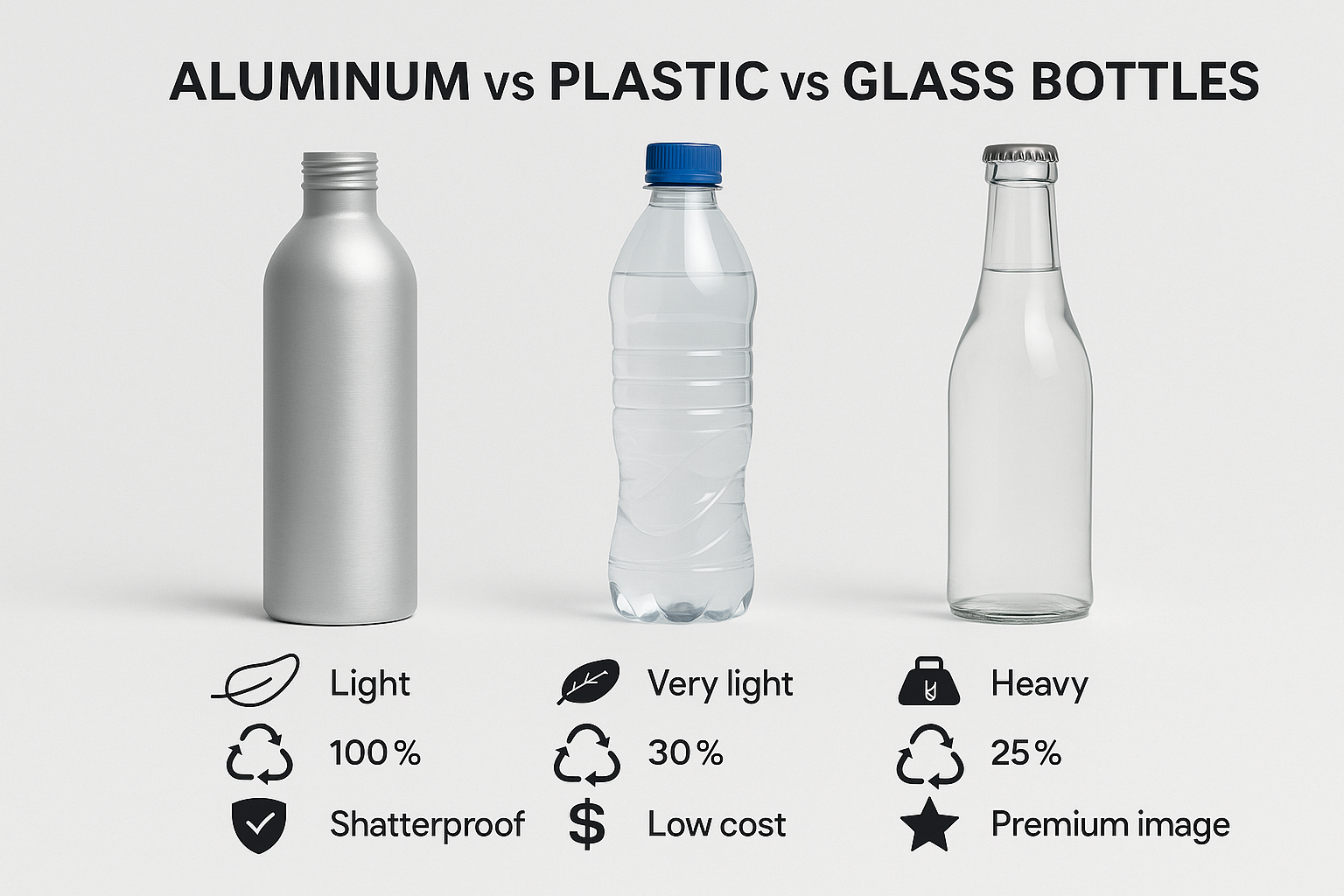

Table 1: Aluminum vs. Plastic Compliance Comparison

| Criteria | Aluminum | Plastic |

|---|---|---|

| Recycling Rate (EU) | 75% | 32% |

| CO₂ Emissions (per kg) | 8.24 kg | 12.5 kg |

| EU 2025 Ban Status | Fully compliant | Banned in most categories |

How Do Aluminum Bottles Reduce Costs While Staying Compliant?

Switching to aluminum isn’t just about avoiding fines—it’s a chance to streamline operations. Here’s how CPI’s clients achieved both:

- Lightweight Design: Aluminum bottles weigh 40% less than glass, slashing shipping costs (e.g., a UK skincare brand cut logistics fees by £12,000/year).

- Recycled Material Savings: Using recycled aluminum reduces production energy by 95%, passing savings to brands.

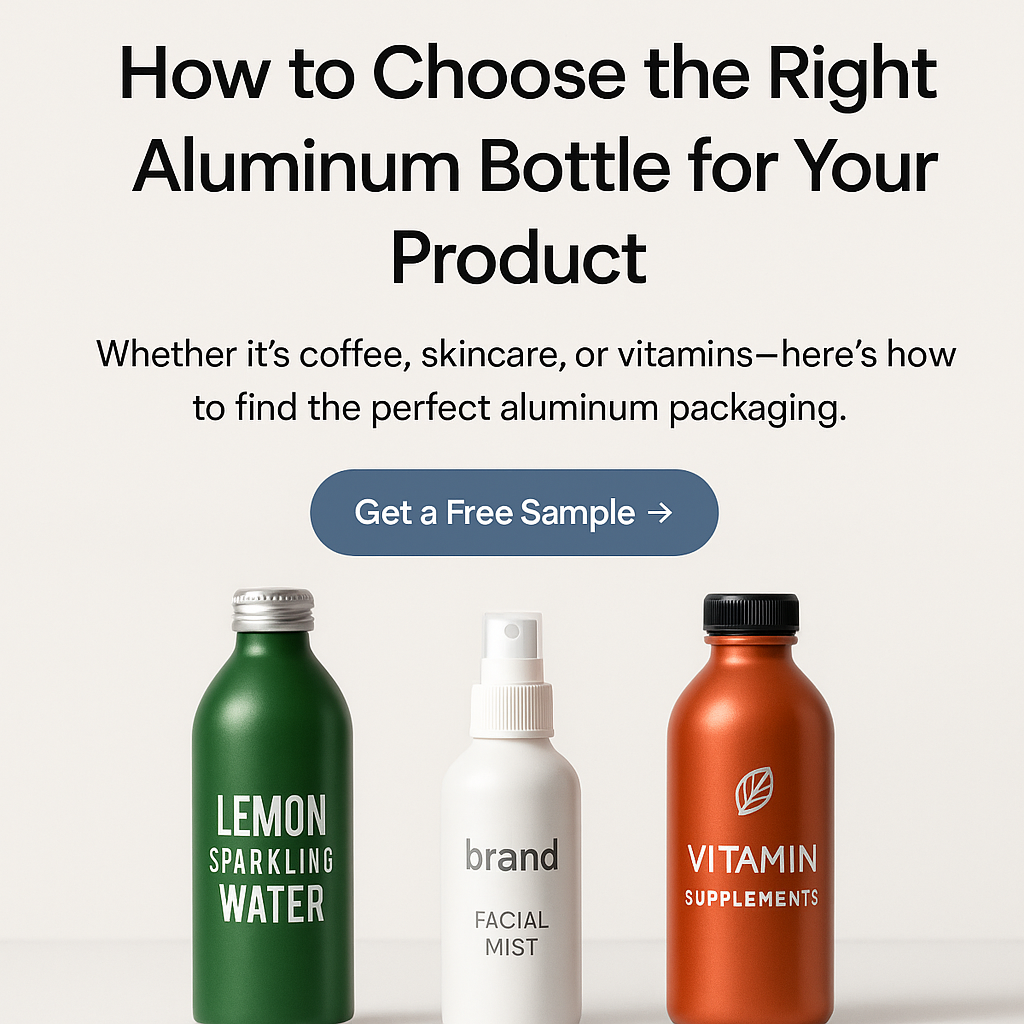

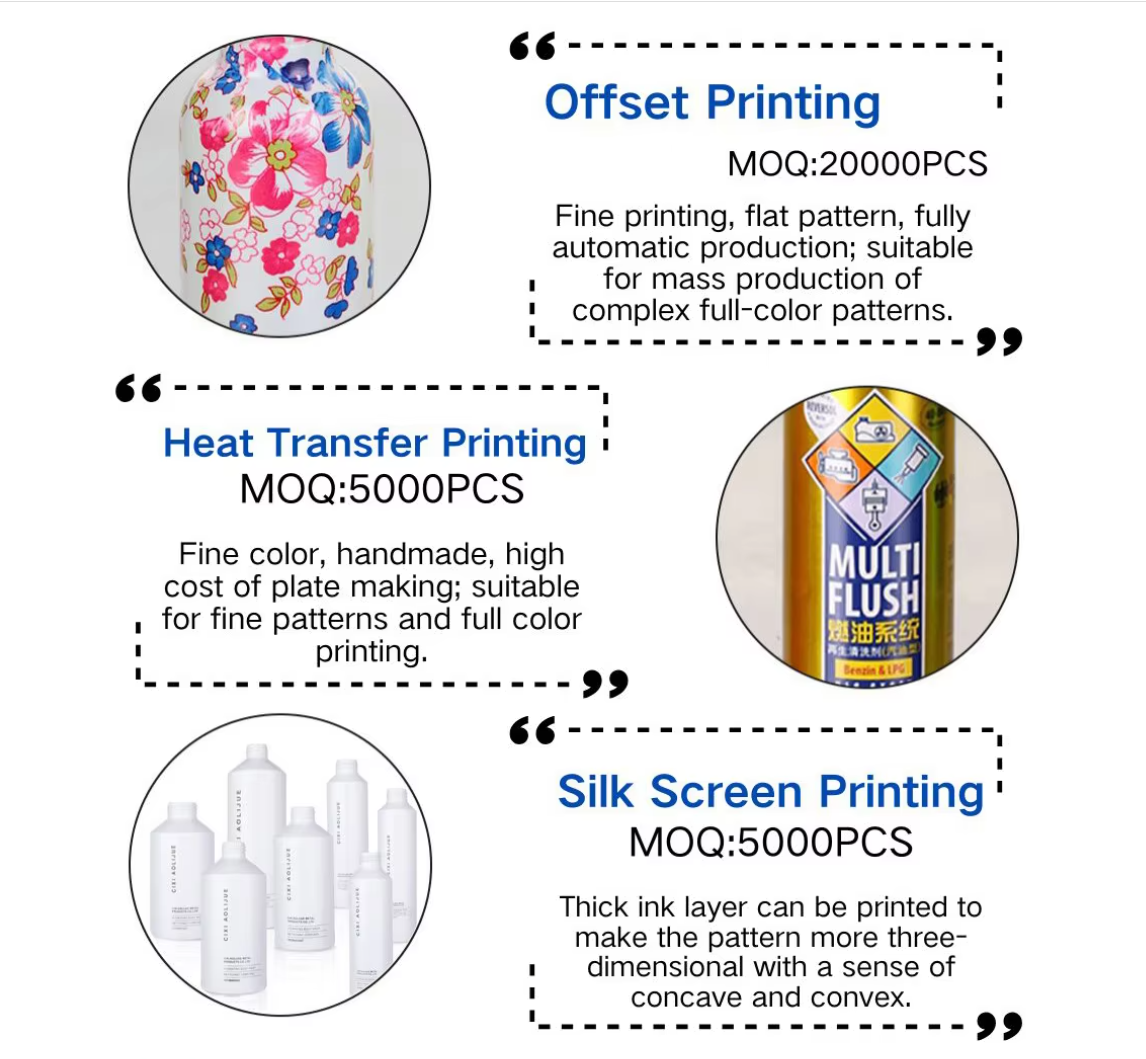

- Customization Flexibility: CPI offers low MOQs (5000 units) and rapid prototyping, eliminating excess inventory risks.

Client Success: Organic Haircare Brand

- Challenge: Needed EU-compliant packaging for new EU market entry.

- Solution: CPI’s 300ml aluminum bottles with child-resistant caps.

- Result: 20% lower per-unit costs vs. glass; 6-month ROI from reduced breakage.

What Do Successful Transitions Look Like? Lessons from Leading Brands

From luxury perfumes to CBD oils, brands are using aluminum bottles to turn compliance into a competitive edge.

- Case 1: Premium Skincare: A UK brand used CPI’s brushed aluminum bottle to highlight “clean luxury” claims, boosting online sales by 34%.

- Case 2: Functional Beverages: A German startup replaced plastic sport bottles with CPI’s 500ml aluminum designs, achieving 100% recyclability and 15% lighter shipments.

- Audit: Identify banned plastics in your lineup (e.g., PS food containers).

- Prototype: Test CPI’s aluminum samples with your product (2-week lead time).

- Launch: Use CPI’s certification docs (REACH, FDA) for seamless EU market entry.

Conclusion

The EU’s 2025 plastic ban isn’t a hurdle—it’s an opportunity to future-proof your brand. Aluminum bottles offer compliance, cost savings, and a story that resonates with eco-conscious consumers. With CPI’s expertise in customizable, lightweight designs, your transition can be smooth and profitable.

Ready to ace the EU 2025 deadline? Download CPI’s free Compliance Checklist or request samples at alumbottle.com.