Customizing your aluminum bottle with eye-catching graphics is key to brand differentiation—but which printing method should you choose? Whether you’re a cosmetics brand or beverage startup, selecting the right decoration technique can dramatically impact both the look and cost of your packaging.

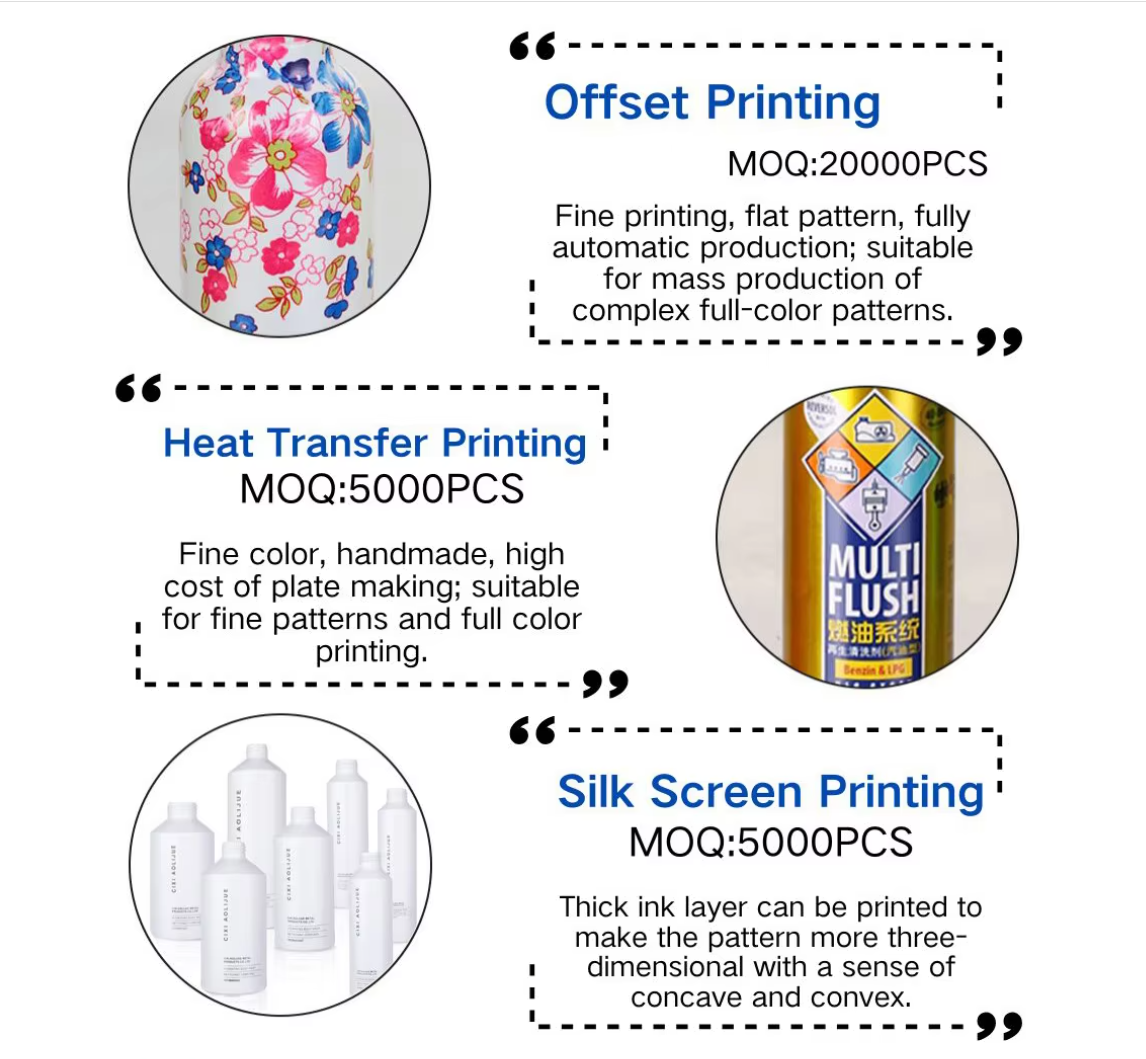

The three most common printing methods used on aluminum bottles are silk screen printing, heat transfer printing, and offset printing. Each offers unique benefits and limitations depending on your design, budget, and order volume.

Let’s break them down so you can choose the most suitable option for your brand.

Why is printing method selection important?

Your packaging is your silent salesperson—it communicates quality, identity, and positioning at first glance. But even the best design can fall flat with the wrong print technique.

The right printing method enhances visual appeal, ensures color consistency, and supports durable performance under handling and moisture.

Understanding the strengths of each method helps avoid printing issues like fading, misalignment, or high costs at low volumes.

What is silk screen printing best used for?

Silk screen (or screen printing) applies ink directly to the aluminum surface using a mesh stencil. It’s ideal for simple logos, text, and solid colors, especially in lower color counts.

Pros:

- Crisp, clean lines and strong ink adhesion

- Cost-effective for 1–3 color designs

- Long-lasting and scratch-resistant

- Great for matte or metallic finishes

Cons:

- Limited to flat or cylindrical surfaces

- Not ideal for complex gradients or full-color images

Silk screen printing is most commonly used for cosmetic bottles, essential oils, and boutique water bottles.

How does heat transfer printing compare?

Heat transfer involves applying a pre-printed image onto the bottle using heat and pressure. It allows for high-resolution, photo-quality images and detailed color blends.

Pros:

- Vibrant, high-definition prints

- Allows gradients and complex graphics

- Suitable for mid-volume runs

- No label seam

Cons:

- Slightly higher cost than screen printing

- Can crack or peel over time if poorly applied

Perfect for lifestyle or promotional bottles that need strong visual impact.

What is offset printing and when should you use it?

Offset printing is a high-speed method used on fully automatic aluminum bottle lines, capable of printing up to 9 colors with remarkable precision.

Pros:

- Allows complex, multi-color designs (up to 9 colors)

- High-definition, consistent print quality

- Ideal for full-wrap branding and gradient effects

- Highly efficient for mass production

Cons:

- Higher MOQ: usually 20,000 pcs minimum

- Long sampling time: samples take as long as regular orders

- High sample cost: around $500 per design

- Not ideal for low-volume or test projects

Offset printing is widely used by established brands with large-scale distribution who need perfect registration, color depth, and consistency across runs.

Which method should you choose for your brand?

Here’s a quick decision guide based on your needs:

| Printing Type | Best For | MOQ | Color Range | Finish Style |

|---|---|---|---|---|

| Silk Screen | Simple logos, fewer colors | 5,000+ pcs | 1–3 solid colors | Matte or gloss |

| Heat Transfer | Medium complexity & vivid detail | 5,000+ pcs | full color | Smooth, semi-gloss |

| Offset Printing | Complex, full-color large runs | 20,000+ pcs | Up to 9 colors | Precise, wraparound |

Ask your supplier for physical samples or digital mockups before committing to large orders. Each method has its sweet spot depending on your brand stage and visual goals.

Conclusion

Your aluminum bottle isn’t finished until your brand is printed on it. Whether you opt for silk screen’s simplicity, heat transfer’s vibrance, or offset printing’s industrial-grade polish, the right technique will elevate your packaging to the next level.

At CPI, we offer all three printing methods with expert guidance and in-house sampling. Want to see what your design could look like?

👉 Contact us today for a free digital mockup or printing sample kit.