Ever thought about turning a simple aluminum bottle into a canvas for your brand? Let's explore how.

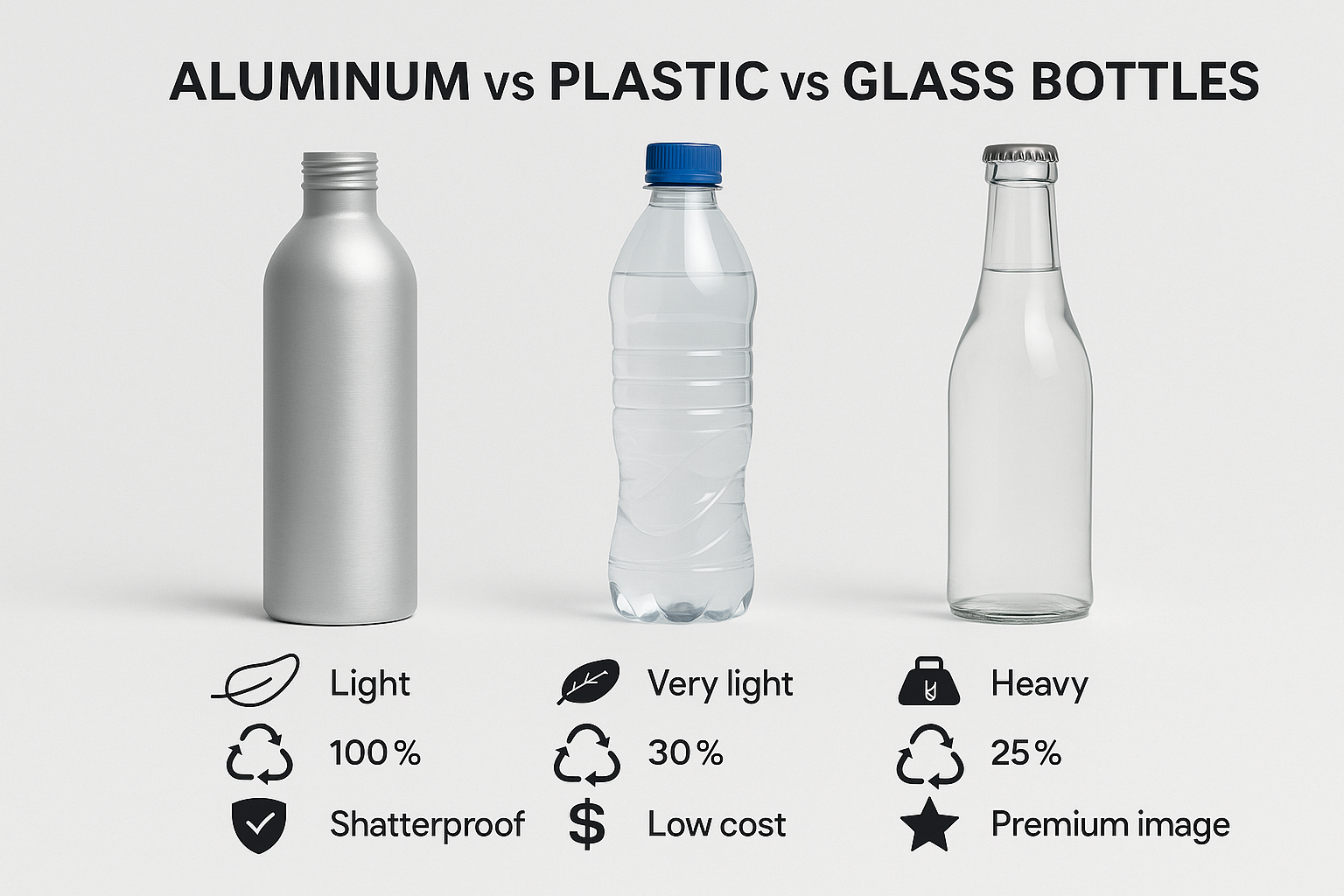

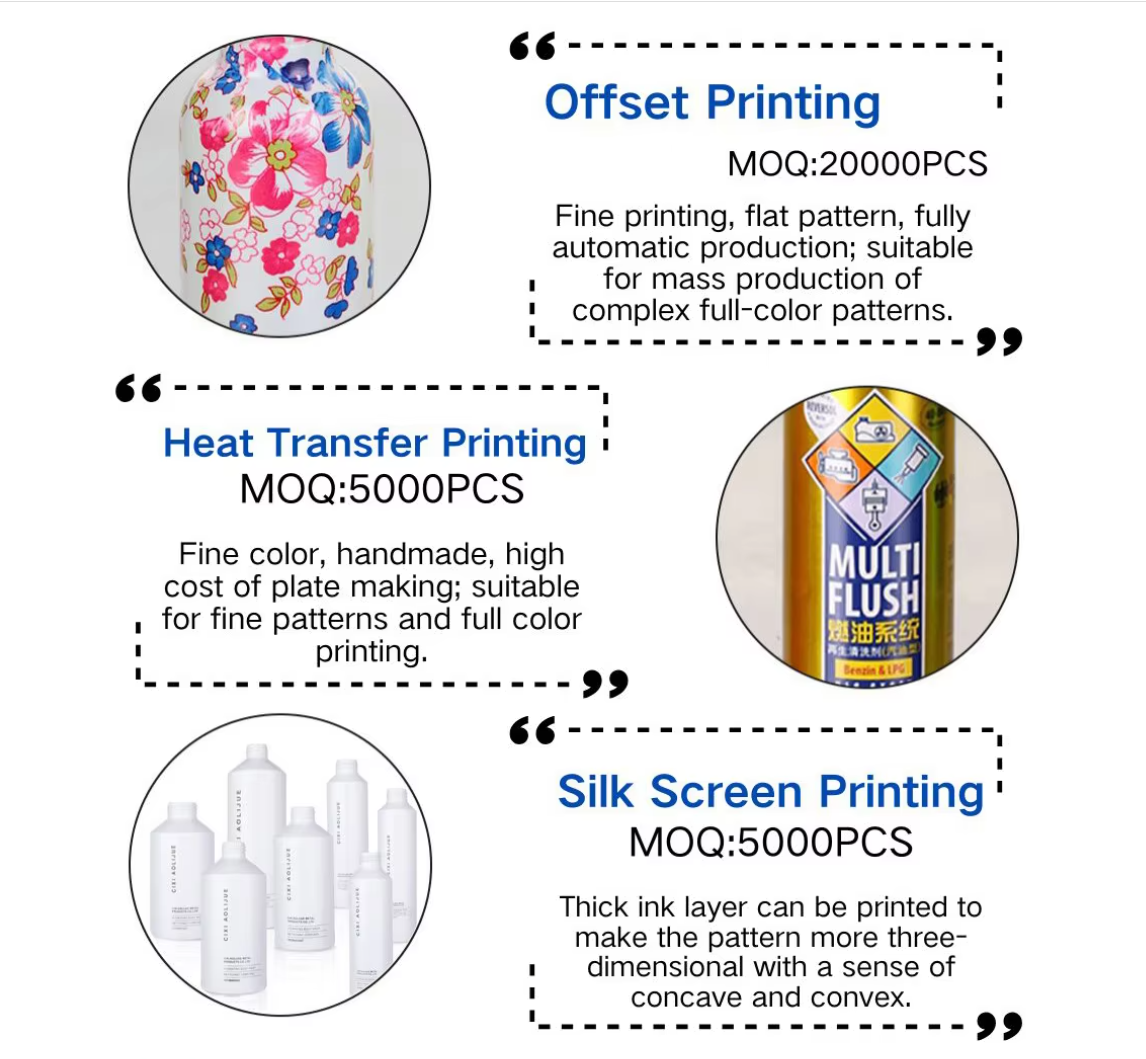

To customize logo printing on aluminum bottles, you can choose between silk screen, heat transfer, or offset printing. Silk screen is budget-friendly for simple designs, heat transfer is great for intricate patterns, and offset printing is best for bulk orders with multiple colors.

Each method has its unique strengths, and picking the right one can seem daunting. I remember grappling with these choices myself when launching a promotional campaign. Delving into each option helped me make the right call and left my audience impressed. Let’s break down each method to help you decide which suits your needs.

Silk screen is best for 1-2 color designs on bottles.True

Silk screen printing is cost-effective for simple designs with 1-2 colors.

Offset printing requires low MOQ for aluminum bottles.False

Offset printing has high MOQ due to its fully automatic production line.

What Are the Benefits of Silk Screen Printing?

When I first stumbled upon silk screen printing, I was amazed by its unique charm and practicality.

Silk screen printing is loved for its cost-effectiveness, durability, and ability to create vibrant designs on various surfaces. Ideal for small color designs and with minimal setup costs, it's perfect for customizing apparel and packaging.

Durability and Longevity

One of the standout benefits of silk screen printing is its remarkable durability. The ink used in this process is thicker compared to other printing methods, which results in a more resilient and long-lasting print. This makes it especially favorable for items that undergo frequent use or washing, such as custom apparel1. This durability ensures that the designs maintain their vibrancy and detail over time.

I remember the first time I received a custom t-shirt with a design that didn’t fade after countless washes. That's when I learned about the magic of silk screen printing. The ink used is thicker than in other methods, resulting in prints that are incredibly durable. This durability means my favorite designs stay vivid and detailed, no matter how often I wear them.

Cost-Effectiveness

When it comes to printing methods, silk screen printing is often celebrated for its cost-effectiveness, particularly for bulk orders. Because the setup involves creating a stencil or 'screen,' the cost per unit decreases as the number of items printed increases. This makes it an economical choice for businesses looking to produce branded merchandise2 or promotional items without breaking the bank.

If you've ever tried ordering custom merchandise, you know costs can quickly add up. Silk screen printing, however, offers a budget-friendly solution. When I ordered a batch of shirts for a family reunion, the per-shirt cost was surprisingly low because the setup costs decrease with larger orders.

Versatility Across Surfaces

Silk screen printing is not limited to fabric; its versatility extends to various materials such as glass, wood, plastic, and metal. This adaptability makes it a preferred option for a wide array of products, from promotional items to industrial labels. Its ability to print on curved or uneven surfaces further enhances its utility in custom product packaging3, adding another layer of appeal to its benefits.

One of my favorite things about silk screen printing is its adaptability. It's not just limited to fabric; I've seen it used on glass, wood, and even metal. This versatility means I can get creative with my projects, whether it's promotional items or personal gifts.

Vibrant and Crisp Designs

The process of silk screen printing allows for the application of vibrant, opaque colors that can produce striking and detailed designs. This method is excellent for achieving high-quality images with bold colors, making it an excellent choice for artwork reproduction or creating impactful brand logos. The precision with which silk screen printing can replicate intricate designs is often unmatched by other methods such as heat transfer4.

I love bold and colorful designs, and silk screen printing delivers just that. The process allows for vibrant colors and detailed images that really pop.

Eco-Friendly Options

With growing concerns about environmental impact, many screen printers are now using water-based inks which are less harmful to the environment compared to traditional plastisol inks. These eco-friendly inks not only reduce environmental footprints but also produce softer prints that are more comfortable on garments.

In a world increasingly focused on sustainability, I appreciate that many screen printers now offer eco-friendly options using water-based inks instead of traditional plastisol inks reduces environmental impact while producing softer prints.

Silk screen is best for 1-2 color designs.True

Silk screen printing is cost-effective for simple designs with fewer colors.

Heat transfer is cheaper than silk screen printing.False

Heat transfer is more expensive due to its complexity and color capacity.

How Does Heat Transfer Printing Work for Complex Designs?

Ever wondered how your favorite complex designs make it onto fabrics or other materials so vividly?

Heat transfer printing for complex designs involves using heat and pressure to apply a pre-printed image onto a substrate. This method creates detailed, multi-color patterns that are both vibrant and durable, making it ideal for intricate artwork on surfaces like fabric or aluminum.

Understanding Heat Transfer Printing

I remember the first time I stumbled upon heat transfer printing while working on a custom project. It was like discovering a whole new world of possibilities for bringing my intricate designs to life. This process starts with crafting your artwork digitally, where you can let your imagination run wild with colors and details. Once that's perfected, it gets printed onto a special transfer paper using solvent ink.

The magic truly happens when you place that transfer paper on your chosen substrate—be it fabric, aluminum, or something else—and apply heat, usually around 375°F, with some pressure. I always picture the ink sublimating from the paper like some sort of alchemical reaction, bonding beautifully with the substrate to reveal a stunningly vibrant design. Unlike silk screen printing5, which limits you to simpler designs, heat transfer allows for precise color control and razor-sharp details.

Advantages of Heat Transfer Printing

One thing I love about heat transfer printing is its ability to handle designs bursting with colors and delicate details, perfect for those special projects where visuals really matter. Plus, the durability it offers is unmatched—no need to worry about your masterpiece fading after a few washes, especially on fabric items like t-shirts or bags.

For anyone like me who’s occasionally running short production runs, this method is also more cost-effective compared to offset printing6, which demands higher minimum orders. The flexibility in substrates—think textiles to ceramics—means I can let my creativity roam free across various materials.

Challenges and Considerations

But, as with all good things, there are a few hurdles to navigate with heat transfer printing. Choosing high-quality transfer paper and ink is crucial; trust me, I've learned the hard way how significantly they affect the final look's longevity and vibrancy.

Another tip from personal experience: nailing the right heat and pressure settings is key. I’ve had my share of uneven transfers and even substrate damage from getting it wrong. So, having precise control over these variables is essential.

While it’s a stellar choice for many projects, it’s worth noting that heat transfer might not be the best fit for three-dimensional objects or those tricky curved surfaces. Each printing technique has its own strengths, so it’s important to match your method to your project's needs. For some tasks, water transfer7 might just be the better route to take.

Silk screen printing is ideal for complex designs.False

Silk screen printing is best for simple designs with 1-2 colors.

Offset printing requires a higher MOQ than silk screen.True

Offset printing uses a fully automatic line, needing higher MOQ.

Why Choose Offset Printing for Large Orders?

Have you ever found yourself staring at a massive print order and wondering how on earth you'll get it done efficiently? Let me tell you why offset printing might just be the answer to your prayers.

Offset printing is ideal for large orders because it combines speed, cost-efficiency, and unmatched quality, making it superior to digital options for bulk projects.

The Efficiency of Offset Printing

When I first ventured into the world of large-scale printing, I was blown away by the efficiency of offset printing. Imagine this: plates made of aluminum, like tiny pieces of art themselves, transferring intricate designs onto rubber rollers, and then onto paper at lightning speed. It's a mesmerizing process that doesn’t compromise on quality. Once you get past the initial setup, it’s like watching a well-oiled machine hum along, producing page after page without missing a beat.

I remember one of my first big projects where time was of the essence. Thanks to offset printing, what seemed like an impossible deadline became manageable. Each sheet zipped through the press swiftly, completing the colossal order with ease. It’s no wonder businesses that need to keep their production lines humming choose offset to optimize their production schedules8.

Cost-Effectiveness in Bulk Production

I’ll be honest; I’m always looking for ways to save money without sacrificing quality. When it comes to large orders, offset printing has consistently proven to be the smartest choice. Sure, the upfront costs for creating those beautiful plates can be steep. But here's the kicker: as you ramp up the quantity, the cost per unit plummets. It’s like buying in bulk at a grocery store—more units equal greater savings.

One time, I was working with a tight budget and a huge print run. The way offset printing cut down on costs without cutting corners on quality was a game changer. Unlike digital printing, where costs don’t waver much with volume, offset allowed us to maximize our budget9 effectively.

Superior Print Quality and Versatility

When you’re aiming for top-notch quality, offset printing is hard to beat. I’ve always been impressed by its ability to deliver precise color matching and crisp details that make each piece pop. The advanced color separation techniques ensure that vibrant colors leap off the page, which is crucial when maintaining brand consistency.

What truly stands out is its versatility. Whether you need a glossy magazine that gleams under the light or a textured brochure that feels special to the touch, offset printing adapts effortlessly. It’s like having a toolbox filled with different paper types and finishes to choose from for any project needs. Exploring these versatile offset options10 opened up so many possibilities for our creative endeavors.

Silk screen printing is ideal for 1-2 color designs.True

Silk screen printing is cost-effective for simple, low-color designs.

Offset printing requires no plate making fees for large orders.True

Offset printing's automation and high MOQ eliminate plate fees.

How to Select the Right Printing Method for Your Brand Needs?

Remember the thrill of unwrapping a product with a perfectly crafted logo? Choosing the right printing method can make or break that moment.

To select the best printing method for your brand, consider design intricacy, color needs, production volume, and budget. Screen printing is ideal for simple designs, heat transfer excels with complex patterns, and offset printing suits high-volume projects.

Understanding Your Design and Color Needs

When choosing a printing method, the complexity and color requirements of your design are primary considerations. I remember when I first dived into selecting printing methods for my brand. It was like choosing the perfect outfit for an event, except this time it was about finding the right fit for my products.

If your design is straightforward, perhaps just a logo or a simple pattern, silk screen printing11 might be your go-to. It's like choosing a classic tee that never goes out of style—affordable and versatile, especially for small batches. Silk screen printing works well for simple designs with one or two colors, offering a cost-effective solution for smaller batches. It's often used in semi-automatic production settings, making it ideal for limited edition products or promotional items.

But what if your design is more like a detailed tapestry? That's where heat transfer printing12 comes in. Imagine needing every color of the rainbow to pop on your product—that's the magic of heat transfer. This method can handle complex patterns and vibrant colors but comes with higher costs. It's particularly beneficial when producing medium to high volumes where the visual appeal is a priority.

Volume and Budget Considerations

Your production volume and budget also heavily influence the choice of printing method. When I was working on scaling up my brand, I quickly realized that volume was king.

For massive runs where uniformity is key, offset printing13 felt like a revelation. It's akin to buying in bulk at Costco—you're getting top-notch quality without breaking the bank per piece. Offset printing supports up to eight-color logos and operates on fully automatic lines, allowing consistent quality across thousands of units without significantly impacting per-unit costs.

And let’s not forget about budget. If you’re anything like me, striking that balance between cost and quality can be tricky. For brands looking to minimize costs while maintaining quality, understanding the MOQ (Minimum Order Quantity)14 is essential. Offset printing usually has high MOQ requirements but offers cost benefits in volume.

Aligning Printing Method with Brand Goals

Lastly, it’s all about aligning with my brand’s values. For me, sustainability is a big deal.

Consider how each method aligns with your brand's overall goals. If environmental sustainability is a core brand value, explore options with eco-friendly inks and materials because I wanted my products to not just look good but also do good.

On the flip side, if luxury is your brand's calling card, consider methods offering premium finishes—think of it as opting for a designer label that speaks volumes.

For brands focusing on luxury markets, prioritize methods that deliver premium finishes such as metallic inks or specialty coatings.

By weighing these factors—design needs, volume and budget considerations, and brand alignment—I’ve been able to make informed choices that resonate with my customers and stay true to my brand’s essence. Evaluate all these factors to align your choice of printing method with the broader strategic objectives of your brand. This ensures not only quality and consistency but also maximizes the impact of your printed materials within your target market.

Silk screen printing is costlier than heat transfer.False

Silk screen printing is cheaper than heat transfer, not costlier.

Offset printing requires a high MOQ due to automation.True

Offset printing uses fully automatic lines, needing high MOQ.

Conclusion

Explore methods for customizing logo printing on aluminum bottles, including silk screen, heat transfer, and offset printing, each suited for different design complexities and production volumes.

-

Learn how silk screen printing withstands frequent use and washing. ↩

-

Discover why silk screen is economical for large orders. ↩

-

Explore how silk screen adapts to various materials. ↩

-

Compare design quality between silk screen and heat transfer. ↩

-

Discover why silk screen printing limits design complexity. ↩

-

Compare costs and quality between offset and heat transfer methods. ↩

-

Explore how water transfer suits complex curved surfaces. ↩

-

Discover strategies to streamline your production timelines effectively. ↩

-

Explore how offset printing can offer cost savings for large orders. ↩

-

Find out how offset printing caters to various print needs. ↩

-

Learn about the applications and benefits of silk screen printing. ↩

-

Explore the process and advantages of heat transfer printing. ↩

-

Discover why offset printing is ideal for bulk orders. ↩

-

Understand how MOQ impacts printing costs and decisions. ↩