Imagine this꞉ You walk down the aisle and an unusually shaped bottle draws your attention.

Aluminum bottles have a problem. Machines don’t create square or other interesting shapes. This is because of how factories build them. Bottles usually look round. Factories give them different shoulder. Shoulders might be round, oblique, bullet or unique. Each look serves a purpose. Each design meets different style needs.

Although these limits seem restricting, many creative options remain. Exploring these unique shoulder designs is like choosing the best outfit for a brand. A classic round shoulder gives a timeless appearance. An edgy oblique design offers a modern feel. Each shape tells a story. These details match packaging with a brand's vision, similar to accessorizing personal style.

Aluminum bottles can be customized into square shapes.False

Manufacturing limitations prevent aluminum bottles from being square.

Different shoulder designs offer aesthetic and functional variety.True

Shoulder styles like round and oblique provide diverse branding options.

What Are the Common Shoulder Designs for Aluminum Bottles?

Have you ever thought about why aluminum bottles look so fashionable and useful at once? Let's explore how shoulder designs transform these bottles into something unique.

Aluminum bottles often have round, oblique, bullet or unique shoulder shapes. These designs serve specific looks and functions. The round shoulder is very versatile. Many people use it.

Exploring Shoulder Designs in Aluminum Bottles

Picture sipping from an aluminum bottle that feels perfect in your grip. This is no coincidence! Designers shape these bottles with special shoulders, each adding style and function. Let's examine four popular designs:

| Shoulder Type | Description | Applications |

|---|---|---|

| Round | Smooth and classic; like a little black dress, simple and flexible. | Suitable for everything from personal care1 to beverages2. |

| Oblique | Slanted design; shouts elegance and creativity. | Very classy, ideal for fashion-forward brands. |

| Bullet | Sleek form; helps a product stand out. Best with certain sizes like 50mm or 58mm. | Perfect for unique markets and novelty products. |

| Special | Brings industrial items to mind; useful for specific applications. | Specifically crafted for special uses like industrial oils or inks. |

Round Shoulder Design

My first time with an aluminum bottle, I felt its round shoulder - smooth and classic. It's adaptable, making it ideal for various industries.

Oblique Shoulder Design

Next, the oblique shoulder caught my attention in a fancy store. This slanted design shouts elegance and creativity.

Bullet Shoulder Design

The bullet shoulder helps a product stand out at trade shows with its sleek form, perfect for niche markets.

Special Shoulder Design

Lastly, the special shoulder brings industrial items to mind - useful and specifically crafted for special uses like oils or inks.

Knowing these designs aids in picking the right appearance for your brand. It also helps your product catch eyes on the shelf while fulfilling its practical purposes. Interested in how aluminum bottle production3 incorporates these designs? Mixing creativity with practical use is the secret to satisfying various needs.

Round shoulder design fits any bottle diameter.True

The round shoulder design is adaptable, fitting various diameters.

Bullet shoulder designs are common in all industries.False

Bullet shoulders are niche, suited for specific diameters and products.

Why Are Cylindrical Shapes Standard for Aluminum Bottles?

Have you ever thought about why aluminum bottles usually have a smooth, round design?

Aluminum bottles usually have round shapes. This shape is strong and sturdy. It is easy to produce and store. The design reduces material waste. It saves space. Very functional for many uses.

The Engineering Behind the Cylindrical Design

Cylindrical shapes are very popular in the aluminum bottle world. Think about squeezing a balloon; it stays firm because the pressure spreads evenly. Cylindrical bottles work the same way, providing superior structural integrity4. They spread pressure evenly, enhancing their strength and resistance against damage. Every dented bottle is probably trying hard to fight off pressure from outside.

Manufacturing Efficiency

Now, let’s see how these bottles are created. The process is really interesting! Picture aluminum moving smoothly into that round shape through seamless extrusion5 processes. This method reduces waste and cuts costs, making production quick and satisfying when everything fits perfectly.

| Advantages | Details |

|---|---|

| Material Efficiency | Minimizes waste during production. |

| Cost-Effectiveness | Reduces overall manufacturing expenses. |

| Production Speed | Facilitates rapid production cycles. |

Storage and Transport Benefits

Storage and transport are very important for businesses with lots of goods. Cylindrical bottles stack very well, optimizing storage and transport by saving space on pallets or shelves in a warehouse. This is crucial in industries like logistics6, where space efficiency directly impacts costs.

Versatile Application

These bottles are very versatile! From beverages to personal care products like lotions and oils, cylindrical aluminum bottles accommodate different types of closures and labels, making them adaptable for numerous applications. I once saw an art installation using these bottles, showing their use goes beyond the practical.

In summary, choosing a cylindrical shape is not just about looks or tradition but about smart choices for strength, cost-effectiveness, and versatility. A sleek aluminum bottle symbolizes thoughtful design.

Cylindrical aluminum bottles are easier to stack and store.True

Their shape optimizes space, crucial for efficient storage and transport.

Square-shaped aluminum bottles are more cost-effective to produce.False

Cylindrical shapes reduce material waste and production costs, unlike square ones.

How Do Shoulder Designs Affect Product Branding?

Have you ever seen how the shoulders of a jacket or the curve of a bottle transform your view of a brand? These tiny details hold great power. It is truly fascinating.

Shoulder designs affect product branding by sending brand messages and attracting attention. Unique shoulder shapes set products apart in busy markets, strengthening brand identity and helping consumers remember them.

Understanding the Role of Shoulder Designs

I remember when I first noticed how much a simple shoulder design affects how people like a product. It happened at a packaging seminar7. The speaker talked about how different bottle shoulder shapes share different brand messages. For example, a round shoulder quietly says 'classic' and 'reliable.' An angled shoulder loudly declares 'modern' and 'innovative.' My favorite jacket’s structured shoulders always boost my confidence at meetings. These choices subtly affect how consumers see products.

| Shoulder Type | Brand Message |

|---|---|

| Round | Classic, Reliable |

| Oblique | Modern, Innovative |

| Bullet | Futuristic, Cutting-edge |

| Special | Niche, Exclusive |

This table shows how different shoulder styles fit with your brand story.

Influence in the Fashion Industry

In fashion, shoulder designs do more than just look nice. They reflect a brand's style. I once got a blazer with perfectly structured shoulders for a big event. The design didn’t just look good; it changed my posture and confidence. I felt ready for anything. Structured shoulders mean authority and professionalism in clothes, while slouchy shoulders suggest comfort and a laid-back vibe.

Learning these effects helps designers decide the best way to show their brand identity8.

Strategic Brand Positioning

Choosing the right shoulder design feels like adding the perfect accessory. It changes a product from ordinary to special. I spent years working with businesses wanting to stand out in busy markets. These designs truly become visual differentiators9.

Knowing your audience’s tastes and the effects of design elements means you can choose wisely. This understanding very much matters for good brand positioning.

Carefully thought-out shoulder designs let brands grab attention and show their true values and promises without saying a single word.

Round shoulders convey reliability in branding.True

Round shoulders are associated with classic and reliable brand messages.

Oblique shoulder designs suggest tradition.False

Oblique shoulders are linked to modern and innovative brand messages.

What Are the Limitations of Aluminum Bottle Customization?

Have you ever thought about why aluminum bottles have particular shapes? Their customization options face restrictions.

Aluminum bottle adjustments hit limits mainly because of how they are produced, their material traits and design limits. Shapes are usually round with set shoulder designs. Changes such as square shapes do not work due to manufacturing barriers.

Shape Constraints and Design Options

Aluminum bottles often stay round because of how they are made. This design constraint limits customization options to specific shoulder shapes like round, oblique, bullet, and special shoulders. Each shape choice gives unique looks and challenges.

- Round Shoulders: These are very common and flexible. They fit any size nicely.

- Oblique Shoulders: These look fashionable and stand out. They are less common but interesting.

- Bullet Shoulders: Slim and modern, like a fast train. Only fit certain sizes (50, 53, 58).

- Special Shoulders: Used for niche products. Very unique, for those who like different styles.

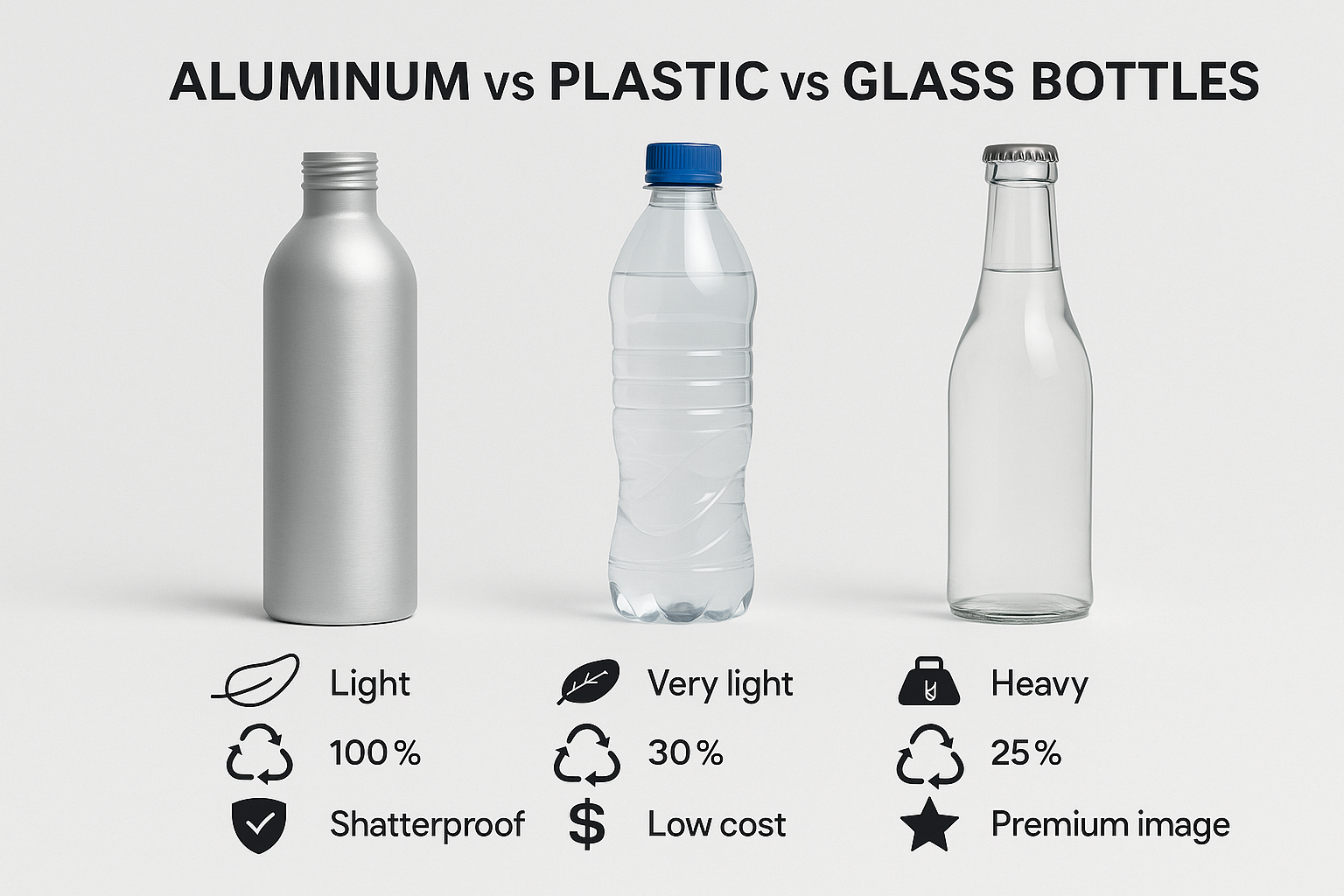

Material Properties and Customization

Aluminum works well because it's durable and light. These qualities matter a lot in packaging but also impose limits. Unlike plastics that can be molded into various shapes, aluminum retains a fixed form once manufactured.

| Design Aspect | Aluminum | Plastic |

|---|---|---|

| Shape Flexibility | Low | High |

| Durability | High | Moderate |

| Environmental Impact | Low | Variable |

Forget about square or odd shapes with aluminum.

Cost Implications

Aluminum brings both eco-friendliness and cost considerations. Bulk production keeps costs low; however, custom designs get expensive due to special tools required for tailored production processes which may not be economically viable for small batch orders.

- Standard Designs: Like a trusty old car - reliable and cheap due to mass production.

- Customized Shapes: Like a high-end sports car - fine if money isn't a problem due to higher costs from specialized tooling.

Health and Safety Considerations

When choosing aluminum for products, I had health on my mind. The health implications10 of using aluminum packaging must be considered during customization. While aluminum is mostly safe for most products, contents may need special linings to stop reactions with acidic contents, adding layers to the process.

Knowing these facts helps steer packaging decisions wisely. Imagination must meet reality; sometimes other materials are worth exploring if specific design requirements cannot be met with aluminum alone.

Aluminum bottles can be customized into square shapes.False

Aluminum's rigidity prevents molding into square or irregular shapes.

Bullet shoulders are limited to specific diameters in aluminum bottles.True

Bullet shoulders are limited to certain diameters like 50, 53, and 58.

Conclusion

Aluminum bottles typically feature round, oblique, bullet, or special shoulder designs. These shapes enhance branding and functionality while facing manufacturing constraints that limit customization options.

-

Discover why round shoulder designs are ideal for universal application. ↩

-

Learn how aluminum bottles with round shoulders serve the beverage industry effectively. ↩

-

Understand the manufacturing process behind different shoulder designs. ↩

-

This link explains how cylindrical shapes enhance structural integrity by distributing pressure evenly, which is critical for packaging durability. ↩

-

Learn how the extrusion process aids in creating seamless cylindrical bottles, optimizing production efficiency. ↩

-

Discover how cylindrical designs optimize storage space and reduce transportation costs in logistics. ↩

-

Understanding how packaging design affects brand identity can provide insights into using shoulder designs effectively. ↩

-

This link will explore how brand identity is crucial in fashion, emphasizing the role of design elements like shoulders. ↩

-

Discover how unique packaging elements, such as shoulder designs, can set brands apart in competitive markets. ↩

-

Learn about the safety considerations of using aluminum for packaging various products. ↩