Understanding logistics sometimes resembles a serious game of chess. Every decision might save money or lose a lot.

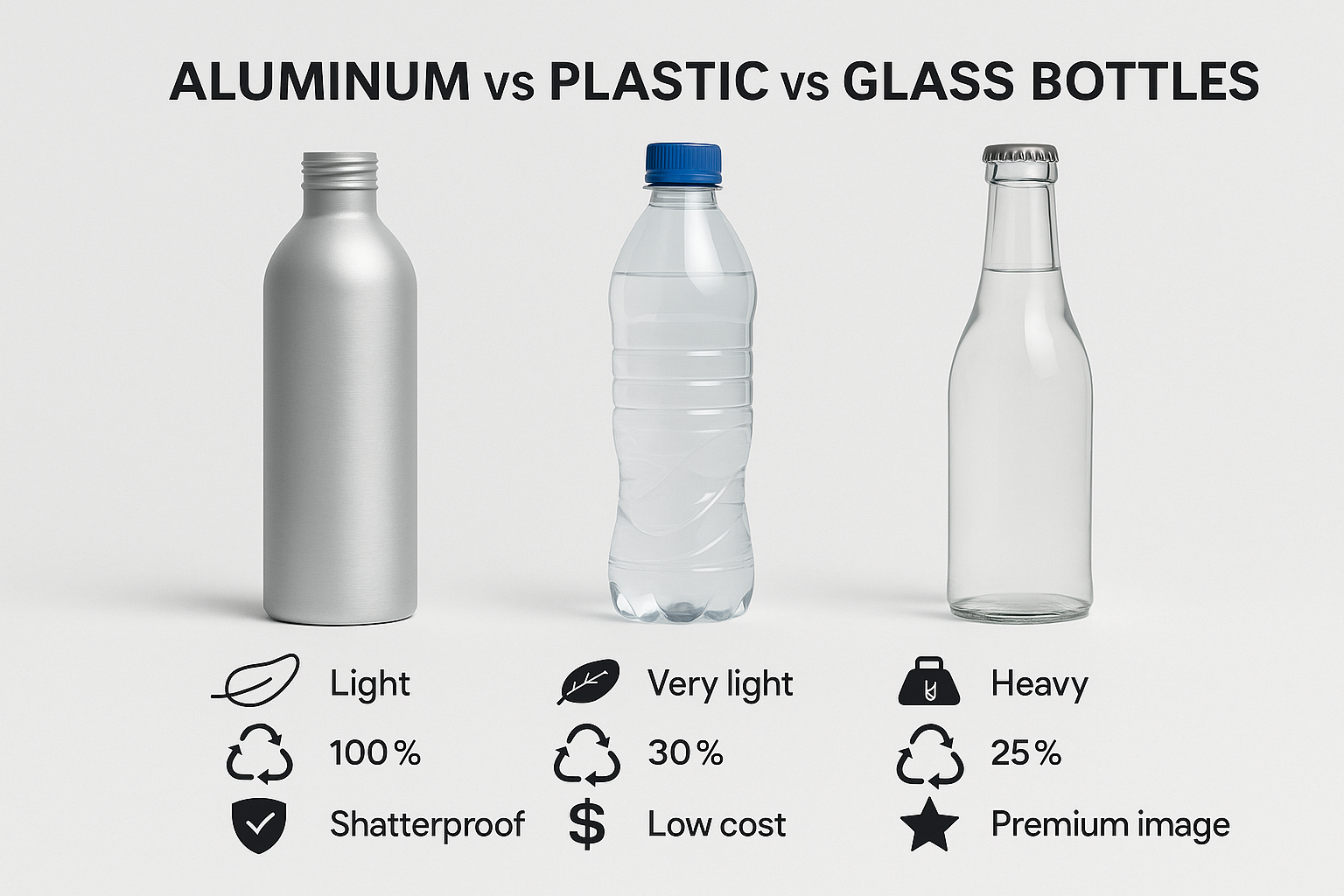

Lightweight aluminum packaging reduces costs in shipping. Businesses achieve efficiency through it. Aluminum lowers transportation weight and minimizes fuel use. This packaging improves recyclability. Many companies choose it for sustainability and operational success. Aluminum is an ideal option for them.

The immediate benefits of lighter loads and fuel savings are clear. Aluminum packaging offers advantages beyond just reducing costs. A small change in packaging could transform logistics strategies. I remember when I first switched to aluminum bottles for my laundry detergent brand. The switch stopped the leakage problems. It also fit well with my commitment to sustainability. This was a win-win situation. Less weight led to lower shipping costs. Better recyclability attracted eco-conscious customers. Opting for aluminum was not only a smart business move. It was a step towards a greener future.

Aluminum packaging reduces shipping costs by 30%.True

Aluminum's lightweight nature significantly cuts transportation costs.

Aluminum packaging is 100% recyclable.True

Aluminum can be recycled indefinitely without losing quality.

How Does Aluminum Packaging Reduce Transportation Costs?

I discovered the benefits of aluminum packaging and felt like I found a hidden treasure in logistics.

Aluminum packaging lowers transportation expenses because it is lightweight. Lightweight materials use less fuel. The strength of aluminum also reduces breakage. Strong packaging leads to less wastage during shipping.

Lightweight Benefit

One day, I examined our shipping bills closely. Weight made a big difference in costs. Aluminum is much lighter than glass. This caught my eye. Transporting all our products with less weight seemed like a dream. When I chose aluminum, fuel usage dropped quickly. This change was a huge win for our budget.

To illustrate, consider a comparison table:

| Material | Weight per Unit (grams) |

|---|---|

| Glass | 500 |

| Aluminum | 150 |

This switch let us pack more products in each shipment. Delivery times improved, and the carbon footprint decreased as well.

Durability and Cost Savings

Aluminum has strong durability1. This changed everything for us. Early on, breakage losses were big with glass. We don’t face those problems now with aluminum. I remember a rough shipment where all bottles stayed safe. I felt very relieved knowing that toughness meant fewer replacements and less waste, keeping costs low.

Space Efficiency

Aluminum's design saves space. I remember reorganizing our warehouse after the switch; suddenly, we had much more room! Stacking them better meant fewer trips, saving costs even more. Businesses seeking to minimize logistics2 costs find this feature very helpful.

Environmental Benefits

Reduced transportation costs help the environment by lowering fuel use and reducing shipments, which helps us reach our sustainability goals. It's not just about cost-saving; it’s also about having a good impact on Earth. Customers noticed and admired our efforts, likely enhancing our brand's image among eco-friendly buyers.

In conclusion, using aluminum packaging changed our logistics management greatly. Its lightweight, strong, and space-saving features make it wise to cut transport costs while supporting eco-friendly actions. If you are thinking about this change, I really vouch for the huge benefits you will see.

Aluminum packaging is lighter than glass.True

Aluminum weighs 150 grams per unit compared to glass's 500 grams.

Glass packaging is more durable than aluminum.False

Aluminum is more durable, reducing breakage and product loss.

How Does Aluminum Enhance Logistics Efficiency?

Have you ever wondered how something as simple as aluminum might transform logistics?

Aluminum is lightweight. It also has a really good strength compared to its weight. These qualities turn aluminum into a logistics powerhouse. It reduces fuel usage and emissions. Its toughness helps in keeping packaging secure. Secure packaging lowers damage during transport. This also probably improves delivery efficiency.

The Lightweight Advantage

I remember when I first understood the impact of aluminum in packaging. It felt like switching from a heavy desktop to a sleek laptop. Aluminum's lightness transforms transportation loads. Reducing weight means lower fuel use3. Less fuel leads to fewer emissions, which aligns with sustainable goals.

Durability and Strength

Think about packing a fragile item for a long journey. You want strong protection. Aluminum shines here with its high strength-to-weight ratio, much like an athlete who is surprisingly strong. Aluminum handles heavy loads without deforming, making it ideal for packaging materials like aluminum cans4. It protects contents during transit, significantly reducing the risk of leaks and breakage.

| Material | Density (g/cm³) | Typical Uses |

|---|---|---|

| Aluminum | 2.70 | Packaging, automotive, aerospace |

| Steel | 7.85 | Construction, shipbuilding |

| Glass | 2.50 | Bottles, jars |

Impact on Supply Chain Processes

Aluminum in supply chains is akin to embracing smart recycling practices. Its recyclability fuels circular economy methods5, leading to less waste and lower costs—a true win-win situation. Companies that choose aluminum often improve brand image and customer loyalty frequently increases as well.

Environmental Considerations

Choosing aluminum shows commitment to the environment due to its recyclability and low environmental footprint during production and transportation. Aluminum supports sustainable practices6 directly, attracting eco-friendly customers and stakeholders—an increasingly important aspect in my work.

Using aluminum in logistics isn't just about efficiency; it's about joining a bigger movement towards sustainability and innovation. Solutions benefit both businesses and the planet, significantly changing global transportation of goods.

Aluminum reduces transportation fuel consumption.True

Aluminum's lightweight nature decreases load weight, leading to lower fuel use.

Steel is lighter than aluminum for logistics use.False

Steel is denser than aluminum, making it heavier and less efficient.

Can Aluminum Packaging Help Lower a Company's Carbon Footprint?

Did you ever think about how something as basic as packaging might really change things?

Aluminum packaging helps reduce a company's carbon footprint because it is endlessly recyclable. This packaging is lightweight. It also needs less energy to produce. Many businesses that focus on sustainability find this a very smart choice. They really want to reduce their environmental impact.

The Recyclability Advantage

I remember the first time I saw how much waste our company produced with plastic packaging. It was a wake-up call. Then I discovered aluminum's magic - it can be recycled repeatedly without losing quality. This endless recyclability reduces waste7 and saves resources. I run a laundry detergent brand, and switching to aluminum was an easy decision. It helps us minimize waste and aligns with my passion for sustainable practices.

| Material | Recyclability | Carbon Emission (per ton) |

|---|---|---|

| Aluminum | Infinite | 4.02 tons |

| Glass | Limited | 6.0 tons |

| Plastic | Limited | 6.41 tons |

Lightweight and Energy Efficient

Another day, another shipment—well, not quite the same. I used to dread the fuel used by trucks hauling our heavy glass bottles. Then came aluminum, which is light as a feather compared to glass. This change reduced our transportation emissions significantly. Plus, the energy savings8 during production help me sleep better at night, knowing we're helping the planet.

Longevity and Durability in Packaging

Leakages were a nightmare for me! Imagine opening a box of returned products because they spilled on the way—heartbreaking and costly. Aluminum's durability ended those worries by ensuring product integrity and minimizing leakage risks—a key concern for my brand. It keeps our products safe, extending shelf life and reducing replacements or returns. This change has greatly improved our operations by maintaining product quality and keeping our customers happy.

Consumer Appeal and Brand Responsibility

Our customers are very smart these days; they care about the planet as much as I do. By using aluminum packaging, I show them we share values of environmental responsibility. It's been incredible to see how this choice improved our brand image—it attracts new eco-conscious customers and creates a culture of sustainability within our team. It's more than business—it's about building a community of like-minded individuals who want to do good in the world together, ultimately boosting brand reputation9.

Aluminum is infinitely recyclable.True

Aluminum can be recycled repeatedly without quality loss.

Plastic packaging has lower carbon emissions than aluminum.False

Plastic emits 6.41 tons of carbon per ton, more than aluminum.

How Does Aluminum Compare to Other Packaging Materials in Terms of Sustainability?

Have you ever thought if aluminum truly stands as the green packaging hero it pretends to be? Join me as I tell my story of exploring the world of sustainable packaging options.

Aluminum packaging is special because it is sustainable. It recycles very easily. It uses less energy in production. Its environmental impact is lower than that of plastics. The global recycling rate for aluminum is 73%. This makes it a top choice in sustainable materials.

The Recycling Advantage of Aluminum

One day, while sipping coffee from an aluminum can, I realized that we often ignore recycling's importance. This thought pushed me to explore aluminum's environmental benefits. Unlike plastic, aluminum keeps its quality no matter how often it gets recycled. It's just like that favorite family dish - it never loses its appeal. Making new aluminum requires a lot of energy; however, recycling it uses only 5% of that energy. This means much less energy use and a smaller carbon footprint. This fact is really important.

| Material | Global Recycling Rate |

|---|---|

| Aluminum | 73% |

| Plastic | 9% |

| Glass | 26% |

Learn more about sustainability10

Energy Efficiency and Production

When I began my laundry detergent brand, sustainability was a constant concern. Producing new aluminum needs a lot of energy initially; however, recycled aluminum offers much greater energy efficiency. In contrast, plastic depends a lot on fossil fuels throughout its life. Using recycled aluminum cuts greenhouse gas emissions by up to 95% compared to new materials. This fact really fits my goal of reducing environmental harm.

Environmental Impact Compared to Plastics and Glass

Every material has its own environmental impact. For example, plastic often pollutes oceans and releases harmful chemicals during production. Aluminum avoids these issues by being very recyclable.

However, it's essential to consider that glass, although also recyclable, is heavier and more costly to transport due to its weight. This factor increases its overall carbon emissions during logistics.

Moreover, I discovered that aluminum does not leak chemicals into products like some plastics do. This makes aluminum a safer choice for products; it is especially suitable for food and drinks when safety is a top concern.

Aluminum excels in these areas, but choosing the best packaging means thinking about the entire lifecycle and recycling setup—it's like picking the right ingredients for a dish—considering how they all work together is crucial.

Ultimately, selecting aluminum or another material should fit your brand's mission and practical needs.

Explore more about choosing sustainable packaging11

Aluminum can be recycled infinitely without quality loss.True

Aluminum retains its properties after recycling, unlike plastic.

Glass has a higher recycling rate than aluminum globally.False

Glass has a 26% rate, lower than aluminum's 73% recycling rate.

Conclusion

Lightweight aluminum packaging enhances shipping efficiency by reducing costs, minimizing fuel use, and improving recyclability, making it a sustainable choice for businesses focused on environmental responsibility.

-

Explore how aluminum's durability can reduce breakage and waste during shipping, thus saving costs. ↩

-

Understand how aluminum packaging optimizes space usage in transportation, lowering logistics costs. ↩

-

Learn how using aluminum in transportation can significantly cut down on fuel usage and emissions, contributing to eco-friendly logistics. ↩

-

Explore the advantages of aluminum cans in transport, focusing on durability and protection against damage during transit. ↩

-

Discover how incorporating aluminum into circular economy models can reduce waste and improve sustainability efforts. ↩

-

Investigate sustainable strategies that leverage aluminum's properties to enhance environmental responsibility in logistics. ↩

-

Learn how recycling aluminum reduces waste and promotes sustainable practices. ↩

-

Discover the energy savings of aluminum production compared to other materials. ↩

-

Find out how eco-friendly packaging enhances brand reputation among consumers. ↩

-

This link provides detailed insights into the environmental benefits of using aluminum as a packaging material. ↩

-

Discover how businesses can select the most sustainable packaging options available today. ↩