What are Aluminum Bottles?

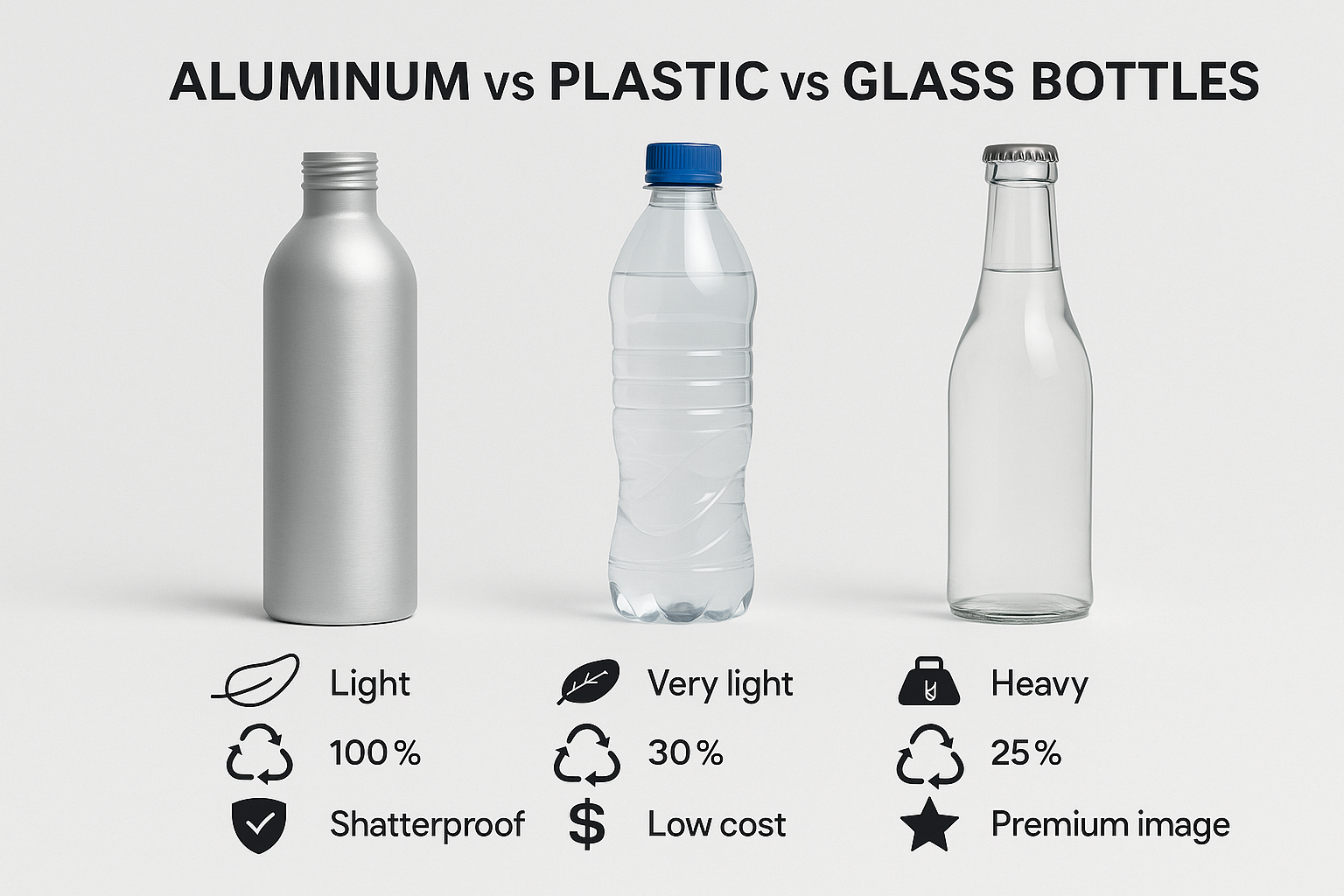

Aluminum bottles are packaging solutions made from aluminum disks (99.78% pure aluminum) through a process involving cold extrusion, necking, internal coating, and printing. These bottles are widely used for various products such as alcoholic beverages, drinks, personal care items, chemicals, and more. Compared to other materials like plastic or glass, aluminum bottles offer several unmatched advantages including being lightweight, having a long shelf life, strong anti-counterfeiting properties, easy portability, and excellent recyclability.

Key Advantages of Aluminum Bottles

- Lightweight: Easier to handle and transport, reducing shipping costs.

- Long Shelf Life: Superior barrier properties extend the shelf life of products.

- Anti-Counterfeiting: Harder to replicate, providing better protection against counterfeiting.

- Portability: Convenient for on-the-go use.

- Recyclability: Environmentally friendly, as aluminum can be recycled indefinitely without loss of quality.

Styles and Accessories of Aluminum Bottles

Types of Aluminum Bottles

Aluminum bottles come in various styles and types, catering to different applications and industries. The primary types include:

- Alcohol Bottles

- Threaded Neck Bottles

- Aerosol Cans

- Essential Oil Bottles

- Chemical Bottles

In this article, let's introduce the 1st type of aluminum bottles : Alcohol Bottles first:

Alcohol Bottles

- Vodka Bottles

- Popular Models: Only produced by semi-automatic lines in China.

- Dimensions: Diameter: 60mm-80mm, Height: 120mm-260mm,

- Inner Caliber: 22mm

- Accessories: Plastic caps with a typically spray-painted matte silver finish.

- Popular Models: Can be produced without plastic sleeves using automatic lines.

- Dimensions: Diameter: 25mm-80mm, Height: 100mm-260mm,

- Neck Size: 20mm/24mm/28mm/38mm

- Accessories: Available with tamper-evident aluminum caps in 28mm and 38mm sizes. The caps can have different liners such as PE, silicone, drop-glue, or injection-molded liners for better sealing.

3. Beer Bottles

- Popular Models: High demand, can be produced on automatic lines with high MOQ.

- Dimensions: Diameter: 59mm, Height: 150mm-240mm

- Accessories: Crown caps, including regular iron caps, tinplate ring-pull caps, and aluminum ring-pull caps.

Applications of Aluminum Bottles

Aluminum bottles are versatile and find use in a wide range of industries:

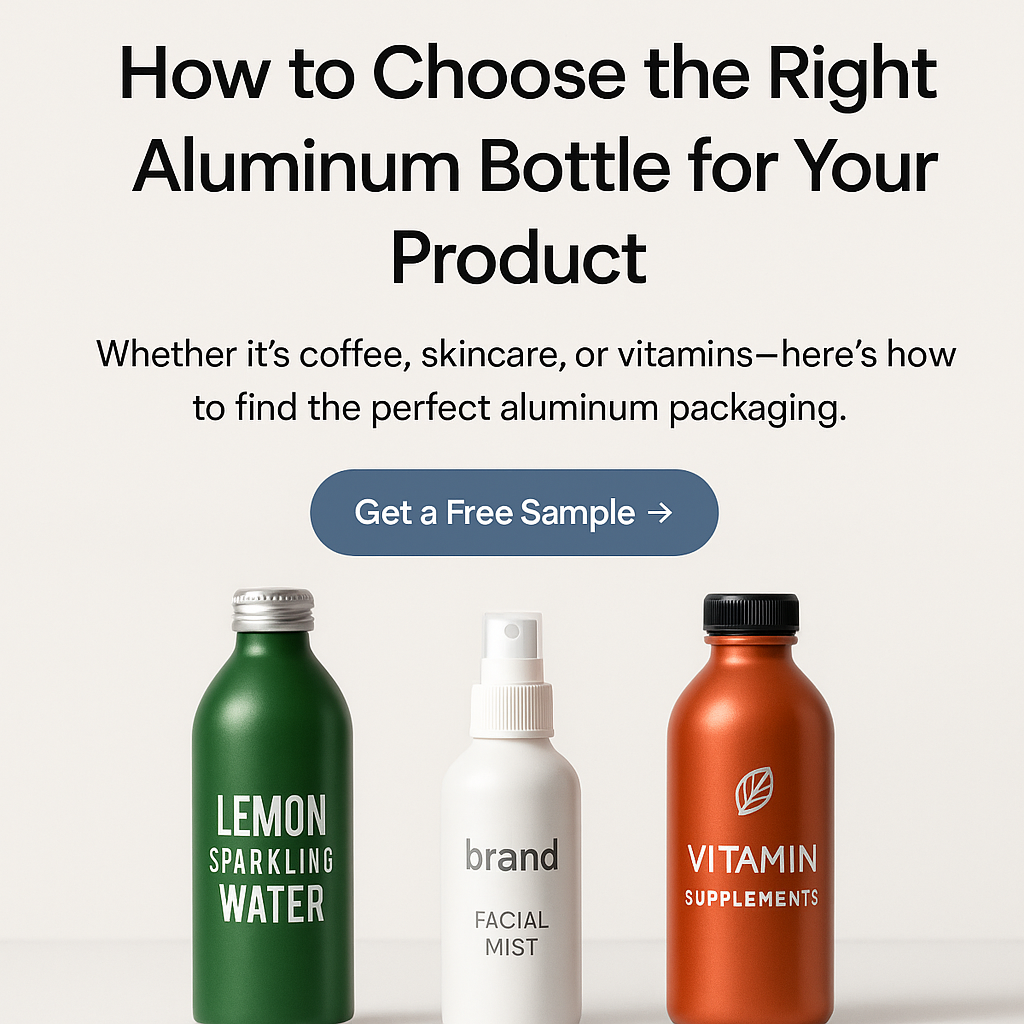

- Personal Care: Shampoos, conditioners, lotions, and creams.

- Cosmetics: Foundations, sprays, and serums.

- Perfumes: High-end fragrances and body mists.

- Beverages: Soft drinks, juices, energy drinks, and alcoholic beverages.

- Essential Oils: Aromatherapy and therapeutic oils.

- Pet Care Products: Shampoos and grooming products for pets.

- Household Cleaners: Cleaning sprays and disinfectants.

- Chemical Products: Solvents, laboratory reagents, and industrial chemicals.

Manufacturing Process of Aluminum Bottles (Semi-auto line)

Step-by-Step Manufacturing Process of Semi-auto production line

- Cold Extrusion: Aluminum disks are cold-extruded to form the basic shape of the bottle.

- Necking: The neck of the bottle is formed to accommodate different types of closures.

- Internal Coating: A protective internal coating is applied to prevent reactions between the aluminum and the contents.

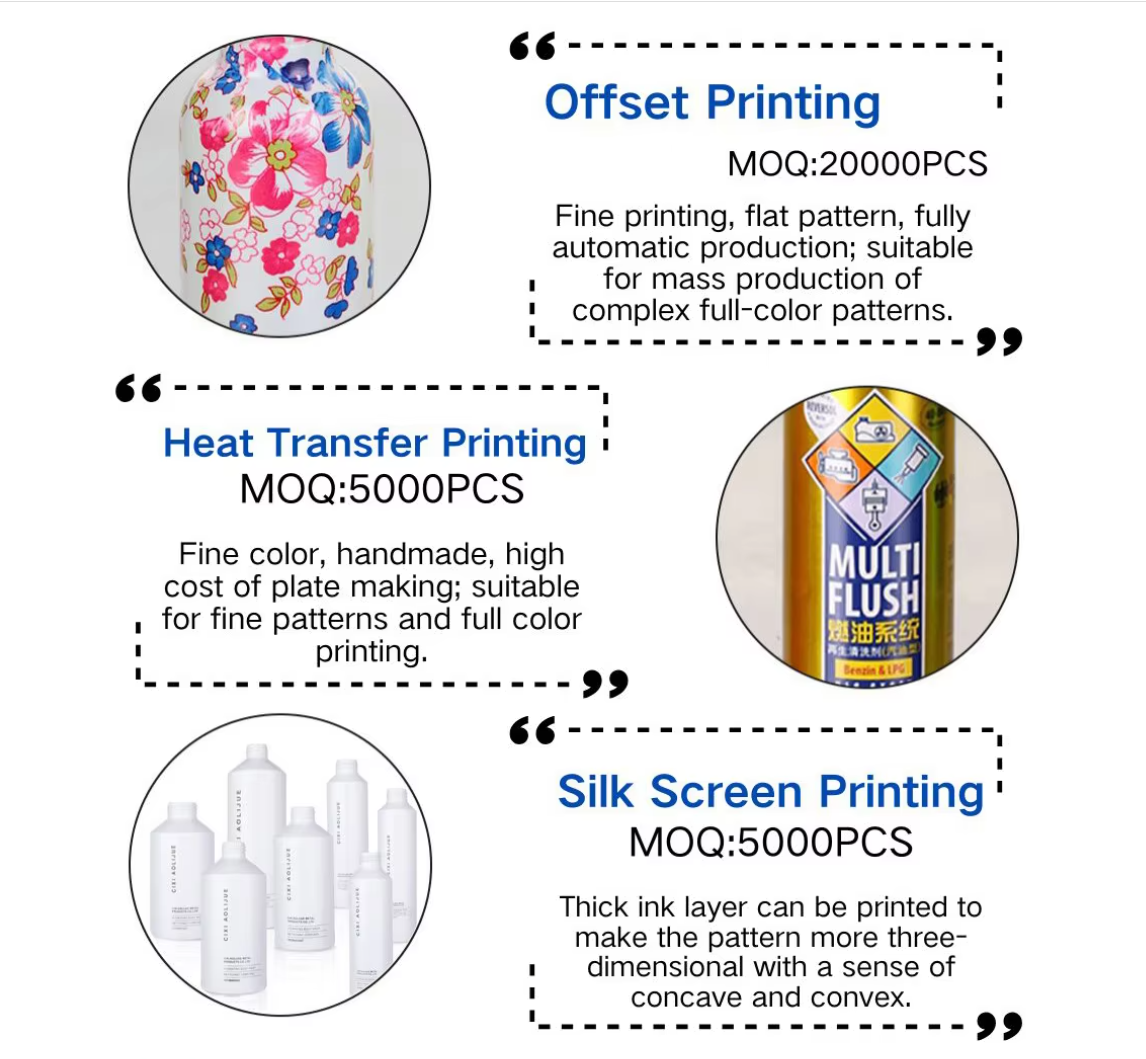

- Printing: Custom designs and branding are printed onto the bottle's surface.

- Quality Control: Each bottle undergoes rigorous quality checks to ensure consistency and durability.

Benefits of Using Aluminum Bottles

Environmental Benefits

- Recyclability: Aluminum can be recycled indefinitely without losing its quality.

- Reduced Carbon Footprint: Lightweight nature reduces transportation emissions.

- Sustainable Packaging: Lower environmental impact compared to plastic and glass.

Consumer Benefits

- Convenience: Lightweight and easy to carry.

- Durability: Resistant to breakage, ensuring safe storage and transport.

- Aesthetic Appeal: Sleek, modern design that appeals to consumers.

Business Benefits

- Brand Differentiation: Unique and high-quality packaging can enhance brand image.

- Cost-Effective: Reduced shipping costs due to lightweight nature.

- Extended Shelf Life: Better barrier properties protect product integrity.

Conclusion

Aluminum bottles offer a versatile, durable, and eco-friendly packaging solution for a wide range of industries. From personal care products to beverages, their benefits are clear in terms of sustainability, consumer appeal, and business efficiency. As technology advances and sustainability becomes increasingly important, aluminum bottles are set to become even more integral to modern packaging solutions.