Manufacturing Process

Aluminum bottles are typically created through impact extrusion or deep drawing, followed by necking and thread-forming steps.

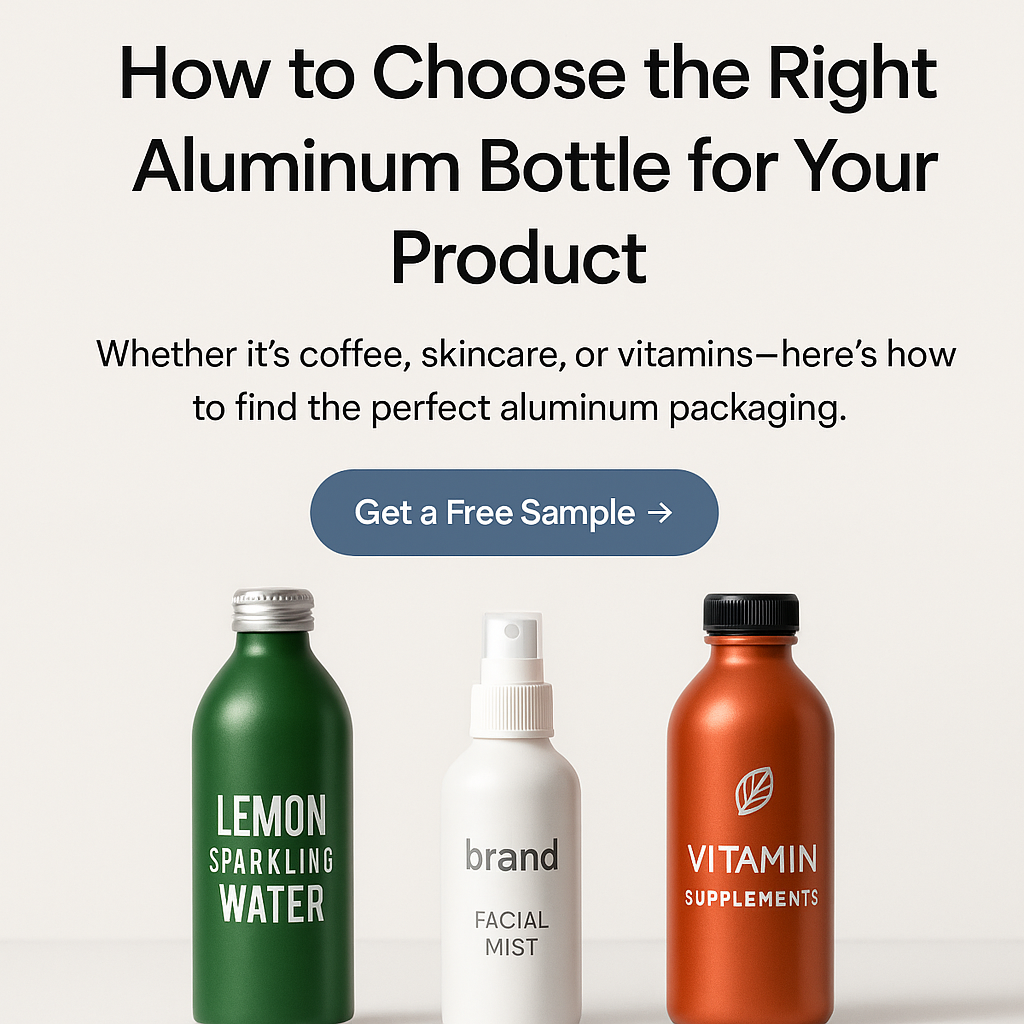

Aesthetic Appeal

These bottles are sleek and minimalist, perfect for packaging lotions, perfumes, and other cosmetic products. They are seamless and can easily accommodate screw caps, plastic caps, lotion pumps, and spray pumps.

Durability

Aluminum bottles are known for their durability. Made from a single piece of aluminum, they have excellent sealing properties.

Superior Atomization

Aluminum bottles are often used for spray products due to their superior atomization. They provide a fine mist that enhances the user experience by making the sprayed liquid feel cool and refreshing.

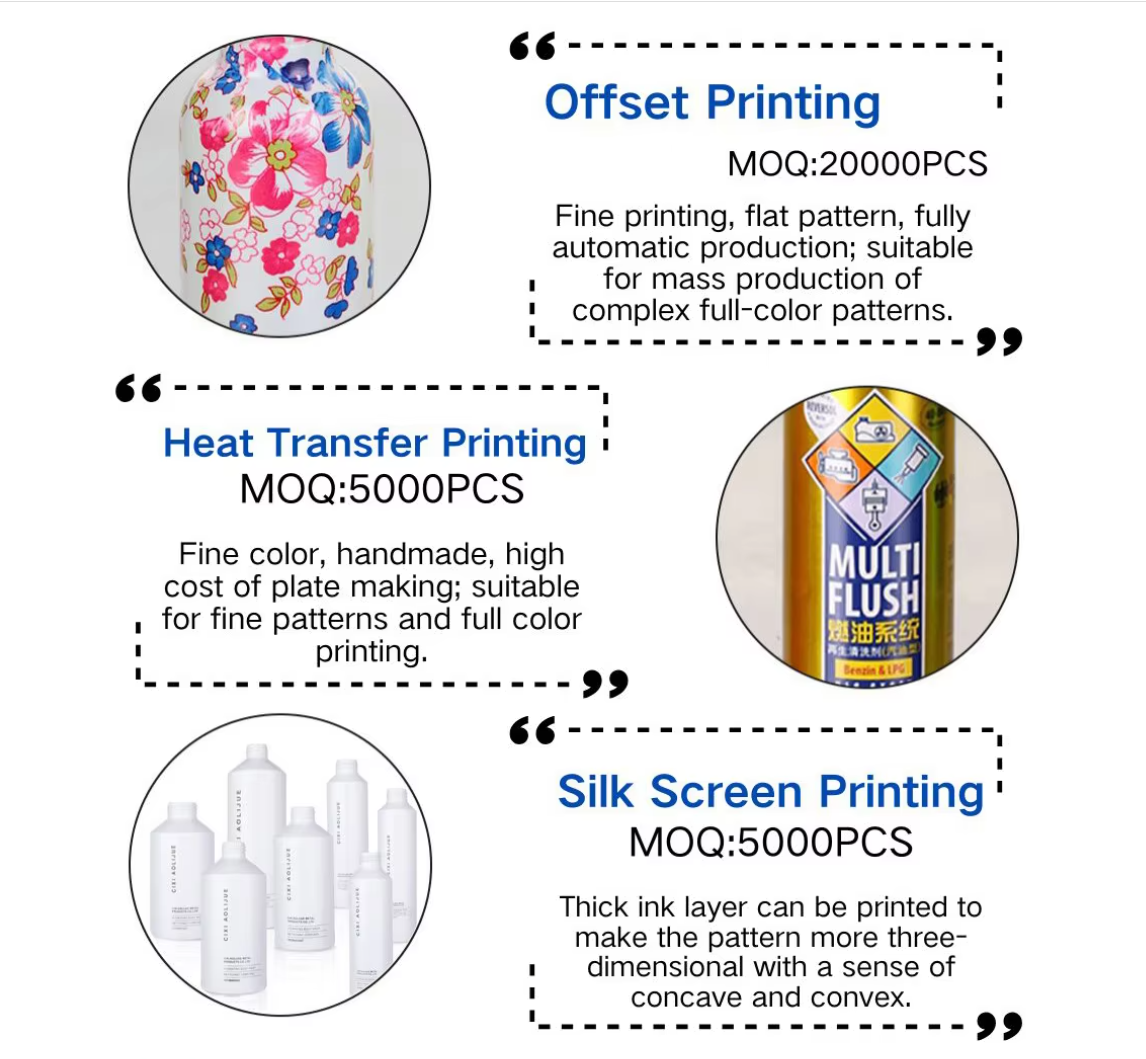

Decorative Options

These bottles can be customized with various processes, including silk screen printing, offset printing, thermal transfer printing, spraying with bronzing, and electroplating. Their attractive appearance helps capture consumer attention.

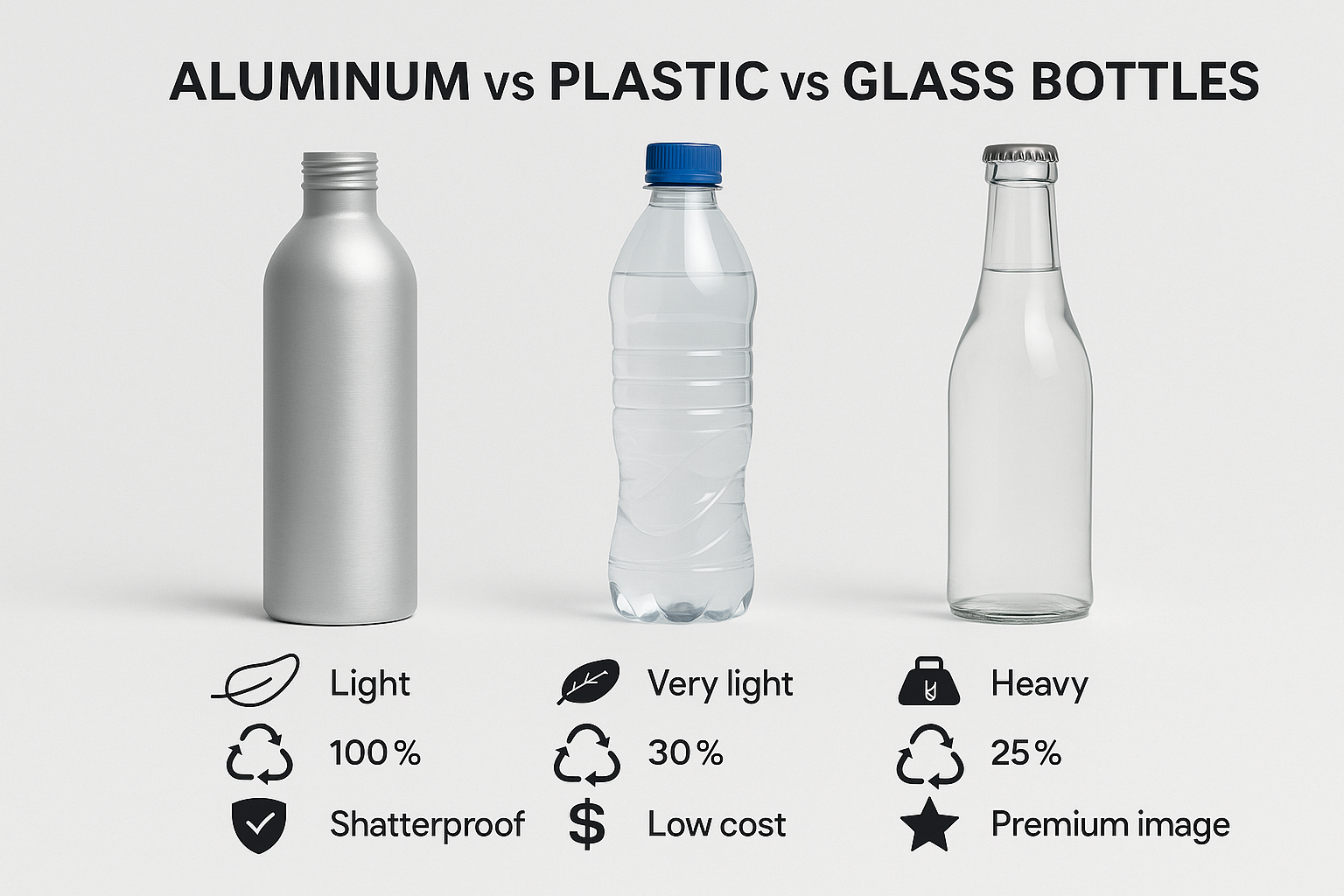

Lightweight

Aluminum’s lightweight nature significantly reduces shipping costs.

Formability

Aluminum is light yet strong, with unique folding characteristics that make it ideal for wrapping a variety of products.

Protective, Hygienic, and Safe

Aluminum bottles are popular with major brands due to their excellent oxygen resistance and barrier properties, often enhanced by an inner coating.

Recyclability

Aluminum bottles are highly recyclable, saving over 100,000 GWh of electrical energy and reducing CO2 emissions by over 90 million tonnes annually.

CPI offers aluminum bottles in various sizes and supports customization. Feel free to contact us anytime for more information.