Did you ever stand in the packaging aisle, wondering whether to pick aluminum or plastic? You are not alone!

Aluminum is often considered more sustainable than plastic for pharmaceutical packaging. Its high recyclability and lower environmental impact contribute to this view. Unlike plastic, aluminum can undergo recycling indefinitely. It retains its quality throughout this process. This characteristic makes aluminum a more eco-friendly choice over time.

Aluminum seems like the sustainability champion at first glance. However, exploring the specific traits of each material shows complexities that might affect your decision. Recycling methods are surprisingly complex. Regulations require navigating through many challenges. Understanding these issues will help you choose the most eco-friendly packaging for pharmaceuticals. I have personally spent many hours thinking about these choices. I really hope to find a perfect balance between sustainability and practicality.

Aluminum can be recycled indefinitely without quality loss.True

Aluminum retains its properties through multiple recycling processes.

Plastic is more recyclable than aluminum for pharmaceutical use.False

Plastic degrades in quality with recycling, unlike aluminum.

How Do Aluminum and Plastic Affect the Environment?

Ever thought about how your packaging choices impact Earth? Aluminum and plastic are everywhere. They leave very different marks on the environment.

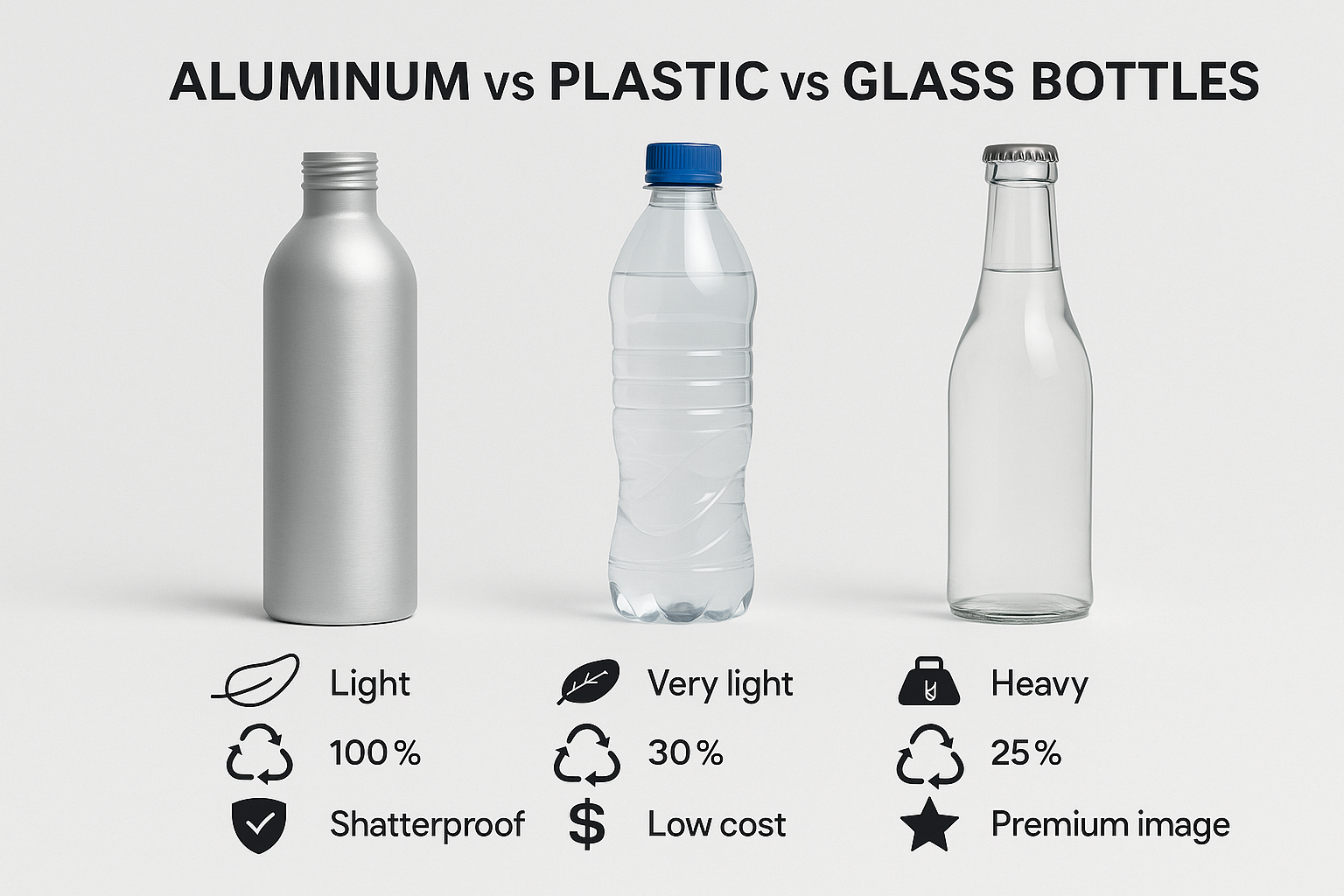

Aluminum uses more energy initially. It is endlessly recyclable. This reduces its long-term environmental harm. Plastic is cheaper at first. However, it causes major environmental problems. Its durability in nature is the main issue.

Energy Use

I remember when I first explored aluminum production. The starting energy need surprised me - it’s very high! But here's the surprising part: aluminum can be recycled many times without losing quality. You can recycle it endlessly. Plastic is different. It uses less energy at first, but recycling it is not as effective.

| Material | Initial Energy Cost | Recycling Efficiency |

|---|---|---|

| Aluminum | High | High |

| Plastic | Low | Moderate/Low |

Greenhouse Gas Release

I saw how aluminum production releases more greenhouse gases than plastic. But there's a good side - aluminum’s recyclability reduces its emissions over time. In contrast, plastics often end up polluting oceans and landfills, contributing to long-term pollution1. They cause lasting problems that don’t vanish.

Waste Handling and Recycling

Imagine a soda can. After use, it could be a new can back on the shelf in just 60 days. This is the amazing thing about aluminum recycling; it doesn't have to stay in landfills. Plastic recycling is trickier. Where you live and the type of plastic can change how much gets recycled, leading to substantial waste management issues that harm our planet.

Lifecycle Look

When I studied these materials’ lifecycles, I realized aluminum has a heavy environmental cost at first. But it improves through recycling, offering a sustainable edge over time. Plastic tells a different story; it has a shorter, less sustainable lifecycle because recycling and breakdown are harder due to limited recycling2 capabilities.

Considering the advantages and drawbacks of these materials involves more than just immediate costs. Long-term sustainability should guide our decisions today for a better tomorrow. For those curious about these topics, exploring industry reports and scientific studies is a great idea for understanding their comprehensive lifecycle impacts3.

Aluminum recycling is more efficient than plastic.True

Aluminum can be recycled indefinitely with minimal quality loss.

Plastic production generates more greenhouse gases than aluminum.False

Aluminum production generates more greenhouse gases initially.

How Do Recycling Processes Differ Between Aluminum and Plastic?

Do you ever think about why recycling certain materials is easy, while others feel confusing? Understanding how aluminum and plastic are recycled might help explain this mystery. Aluminum is usually quite simple to recycle. In contrast, plastic recycling often feels more complicated.

Aluminum recycling is very efficient. It involves melting and remolding. Plastic recycling varies by type. Often, plastic recycling leads to less valuable products, also known as downcycling. Each process has its own environmental impacts. Each also faces unique challenges.

The Process of Recycling Aluminum

The first time I learned about recycling aluminum, I was amazed. The process seemed so simple and efficient compared to other materials. Workers collect aluminum, clean it, melt it, and turn it into shiny new products. Amazingly, aluminum gets recycled repeatedly without losing quality. Those soda cans we toss in the recycling bin? They might become part of a bike or plane someday. This recycling loop is truly remarkable.

A typical flow for aluminum recycling looks like this:

| Step | Description |

|---|---|

| Collection | Gathering aluminum from various sources |

| Cleaning | Removing contaminants and impurities |

| Melting | Heating the metal until it liquefies |

| Remolding | Casting the liquid aluminum into new shapes |

The entire process4 is not just cool; it saves energy too. This is even more true when compared to creating new aluminum from raw resources.

The Process of Recycling Plastic

Recycling plastic feels like a totally different challenge. Many types of plastic exist, each with unique properties. Sorting is key. I’ve seen how workers sort, clean, shred, melt and turn plastic into pellets or new items. However, plastic often ends up "downcycled." This means the final product might not be as durable or high-quality as before.

Consider this simplified version of the plastic recycling process:

| Step | Description |

|---|---|

| Sorting | Separating plastics by type |

| Cleaning | Washing to remove labels and residues |

| Shredding | Breaking down into small pieces |

| Melting | Heating until it becomes malleable |

| Reforming | Molding into new items |

One of the biggest challenges5 with plastic is contamination. Material quality often decreases over time as well.

Environmental Impact and Challenges

When I think about the environmental impact, each material has its unique problems. Aluminum is infinitely recyclable. This fact makes it more sustainable. But mining new aluminum greatly harms the environment. On the other hand, plastic production uses less energy at first but recycling it is really tough.

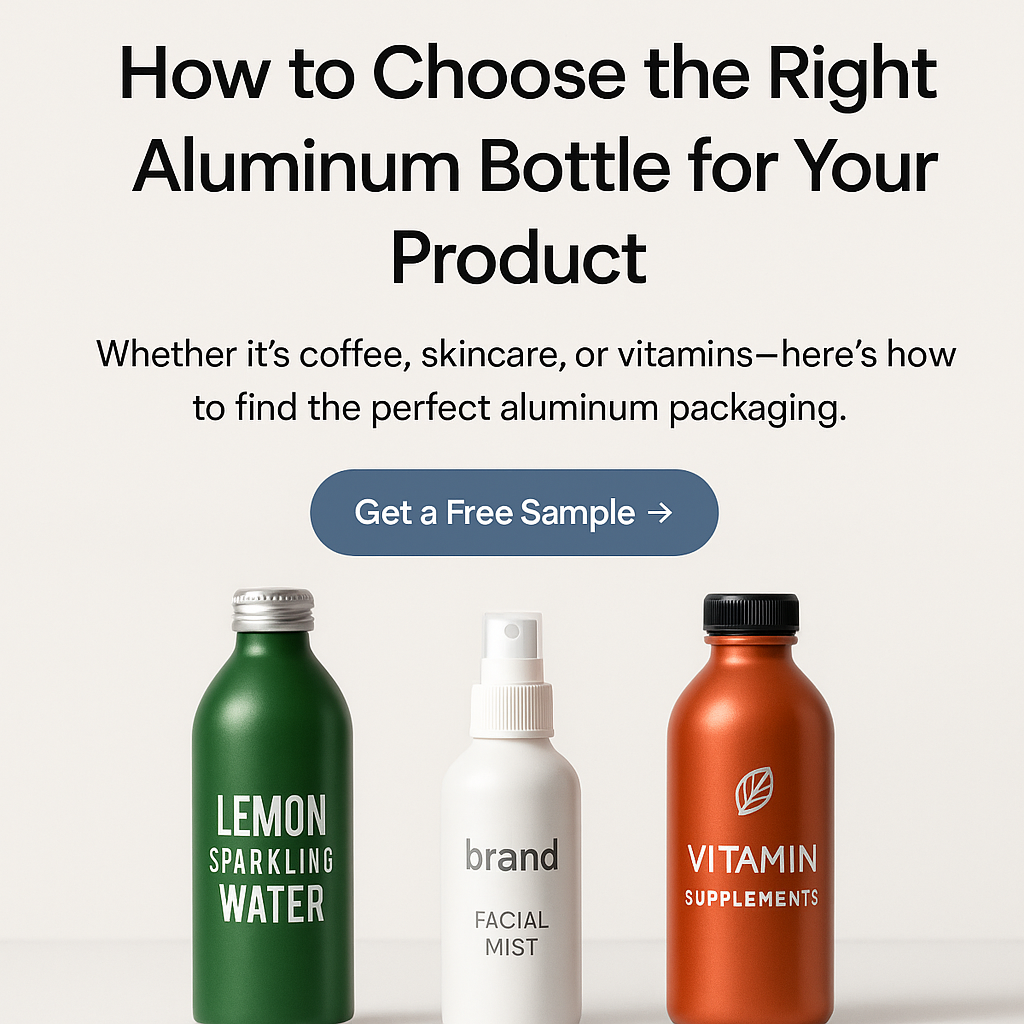

Understanding these differences6 directs our choices toward environmental goals. For example, companies like Matt's laundry detergent brand might choose aluminum packaging to address environmental concerns while handling specific packaging issues.

To learn more, explore how industry leaders break new ground in sustainable packaging7. They are working hard to increase recycling efficiency and reduce environmental harm.

Aluminum can be recycled indefinitely without quality loss.True

Aluminum retains its properties through recycling, allowing endless reuse.

Plastic recycling always results in products of equal quality.False

Plastic often undergoes downcycling, leading to lower quality products.

How Do Regulatory Standards Impact Pharmaceutical Packaging Materials?

Exploring pharmaceutical packaging rules is like entering a world where safety and accuracy are very important.

Regulatory rules for drug packaging materials protect safety, quality and effectiveness. Major organizations like the FDA and EMA provide guidelines. These guidelines cover how to choose materials, labeling details and environmental effects. Following these rules is critical for selling in the market.

Key Regulatory Bodies

Pharmaceutical packaging rules have always fascinated me. They resemble a complex puzzle. Every piece needs to fit correctly for safety purposes. The Food and Drug Administration8 (FDA) in the U.S. and the European Medicines Agency (EMA) guide me. Their strict standards keep packaging materials safe.

Material Selection

Finding the perfect packaging material is a hard challenge. Once, I had to look closely at stability tests. These tests made sure no harmful reactions happened between materials and the drugs they protect. The FDA wants this deep level of examination. The EMA looks at permeability and leachability, ensuring that the contents remain secure until the right time.

Labeling Requirements

Labeling holds a lot of importance. I recall a project focused on making dosage instructions clear. It felt like crafting a detailed recipe—missing one detail could spoil everything. The World Health Organization9 (WHO) stresses clear labels to stop medication mistakes, which I fully support.

| Regulatory Body | Key Focus Areas |

|---|---|

| FDA | Material safety, labeling accuracy |

| EMA | Compatibility, environmental impact |

| WHO | Clear communication, safety instructions |

Environmental Considerations

I care deeply about protecting the environment and appreciate the move towards eco-friendly materials in rules. I always prefer using recyclable or biodegradable choices. The International Organization for Standardization10 (ISO) gives helpful tips for cutting down ecological impacts, which has been really valuable to me.

The Role of Documentation

In my view, documentation shows more than following rules—it reflects process honesty. I detail every test, material source, and labeling step automatically now; these records are vital for audits and highlight the transparency and quality I pursue. Using standard formats like PDFs greatly helps during audits.

| Document Type | Purpose |

|---|---|

| Stability Tests | Material compatibility |

| Labels | Information accuracy |

| Audit Reports | Compliance verification |

Thinking about these experiences increases my respect for regulatory systems—they ensure that our pharmaceutical products remain safe and efficient.

FDA requires packaging materials to be biodegradable.False

FDA focuses on material safety, not specifically on biodegradability.

EMA emphasizes packaging material compatibility.True

EMA sets criteria for material compatibility, including permeability and leachability.

How Do Health Concerns Shape Packaging Material Choices?

People might not realize the packaging of their favorite products might affect their health. Health factors greatly influence how companies design packaging in the world today.

Health is very important when choosing packaging materials. People focus on non-toxic and sustainable options. These choices keep consumers safe. They help protect the environment too. The industry often decides based on these factors.

Understanding the Health Impact of Packaging Materials

I remember first learning about how packaging affects health. A friend talked to me about the plastics in food containers. This conversation opened my eyes to why choosing materials like BPA-free plastics11 is very important. These materials help avoid hormone problems. I also learned that glass and aluminum are often praised for being safe. They stay inactive and do not usually contaminate food.

The Role of Environmental Factors

My family always taught me to recycle and protect the Earth. This upbringing is why I really like eco-friendly packaging, such as recycled paper and biodegradable plastics. These materials cut down on waste and appeal to people who value sustainability. Some brands, like Matt's brand12, are leading in using green solutions. This change shows a move to a more planet-friendly market.

| Material | Health Benefit | Environmental Impact |

|---|---|---|

| Glass | Non-reactive | Recyclable |

| Aluminum | Lightweight | Reusable |

| Bioplastics | Non-toxic | Compostable |

The Influence of Consumer Preferences

Consumers are more aware of health and the environment today. They want to know what's in their products, including the packaging. Brands now give detailed info about their packaging materials due to consumer demand. We see more certifications and labels that promise safety and quality, such as the EU Ecolabel13.

Industrial Compliance and Innovation

Industries like pharmaceuticals and food production must follow strict rules. I noticed innovations like antimicrobial coatings and smart packaging changing the scene. These new ideas address health issues and bring more advanced packaging solutions.

In conclusion, while health may not decide every packaging choice, it really guides innovation in the field. Our focus on safety and being green is reshaping industry standards and changing what consumers want from packaged products.

BPA-free plastics prevent hormone disruption.True

BPA-free plastics are designed to avoid potential hormone-disrupting effects.

Glass packaging is reactive with consumables.False

Glass is non-reactive, making it a safe choice for packaging consumables.

Conclusion

Aluminum is generally more sustainable than plastic for pharmaceutical packaging due to its recyclability and lower long-term environmental impact, despite higher initial energy costs.

-

Understand the detrimental impact of plastic waste on ocean ecosystems and wildlife. ↩

-

Discover why plastic recycling rates are low and the challenges involved. ↩

-

Gain insights into detailed studies comparing the full lifecycle impacts of aluminum and plastic. ↩

-

Learn how aluminum recycling efficiently preserves resources and reduces energy consumption. ↩

-

Explore common hurdles in plastic recycling like contamination and material degradation. ↩

-

Understand the environmental differences between recycling aluminum and plastic. ↩

-

Discover how companies innovate in sustainable packaging to improve recycling. ↩

-

Explore FDA guidelines to understand material safety and labeling requirements, ensuring compliance with US market standards. ↩

-

Learn about WHO's focus on clear communication to prevent medication errors through effective labeling practices. ↩

-

Discover ISO's guidelines on reducing the environmental impact of packaging materials through sustainable practices. ↩

-

Explores how BPA-free plastics contribute to health by preventing hormone disruption. ↩

-

Learn about brands adopting sustainable practices, similar to Matt's brand. ↩

-

Understand how this certification ensures packaging meets environmental standards. ↩