Do you know the Aluminum bottle production process?

We know that aluminum bottles are divided into aluminum bottles produced by automatic lines and aluminum bottles produced by semi-automatic lines. What are the production processes of the two? Today I will introduce this content to you.

Due to different production equipment, the production processes of the two are also different. The biggest difference between the production processes of aluminum bottles on semi-automatic lines and fully automatic lines is that the aluminum bottles on semi-automatic lines are necking first and then processed inside and outside treatment; while the aluminum bottles on (fully) automatic lines are necking after the internal and external processing. The following are the production process diagrams of aluminum bottles on semi-automatic lines and fully automatic lines:

How to distinguish between aluminum bottles on semi-automatic lines and (fully) automatic lines?

1. The best way is to look at the neck of the aluminum bottle: Because the aluminum bottles on the automatic line are offset printed first and then necking, the neck of the aluminum bottles on the automatic line will be matte.

2. The second is to look at the bottom of the aluminum bottle: The bottom of all aluminum bottle on the automatic line is cleaned(raw material color), while the bottom of aluminum bottle on the semi-automatic line will have spray paint colors by default.

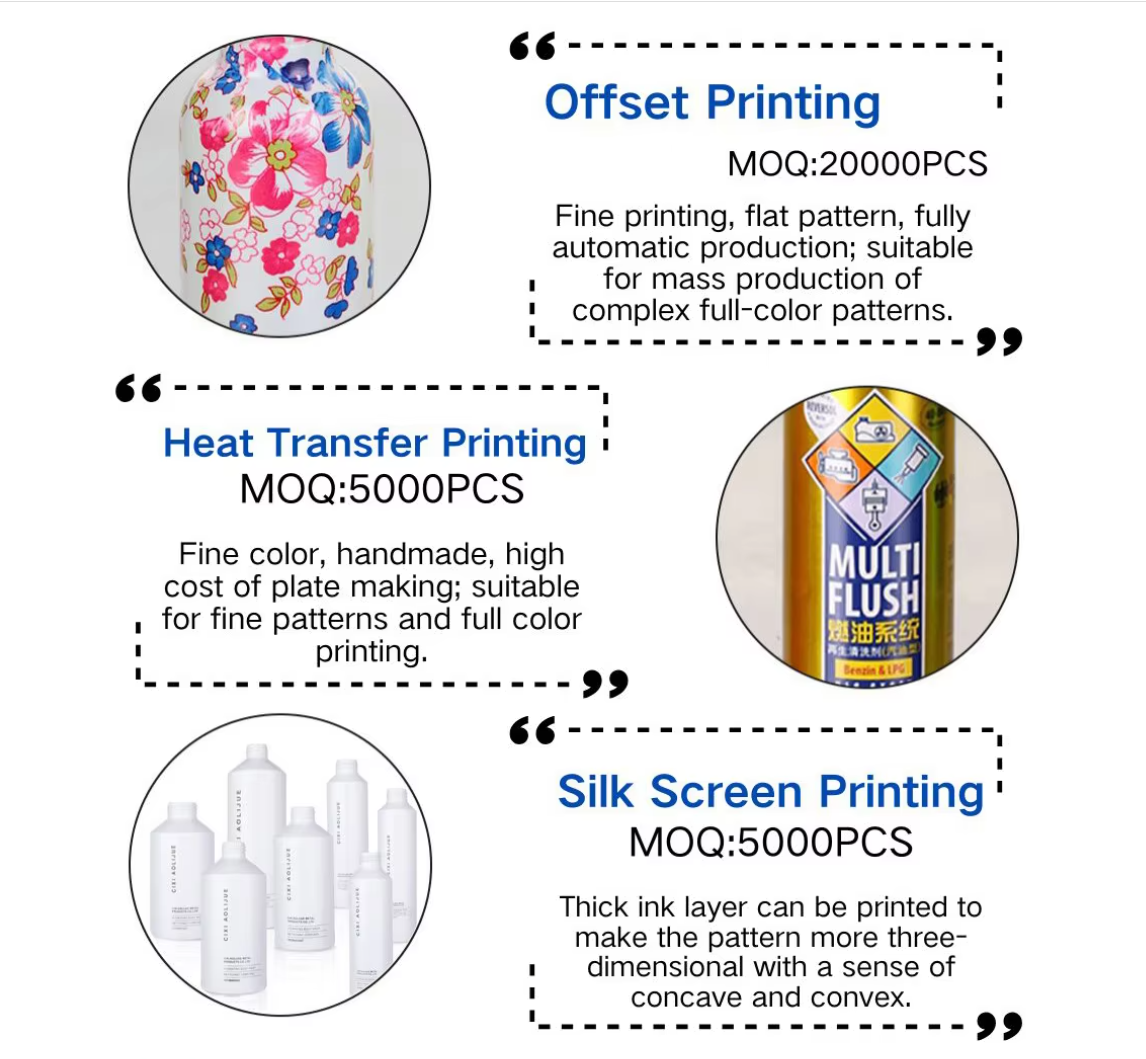

3. Printing method: If the aluminum bottle is screen printed or thermal transfer printed, it is usually a semi-automatic line; if it is offset printed (usually the aluminum bottle neck has a LOGO; if it is a colored base, there will be an obvious seam), it is an automatic line aluminum bottle.

4. Weight of aluminum bottle: Usually automatic line aluminum bottles are lighter than semi-automatic line aluminum bottles.

5. Threaded mouth: The threaded mouth of the automatic line is the original color of aluminum (without spray paint), while the threaded mouth of the semi-automatic line aluminum bottle is generally painted. Of course, now our semi-automatic line can also do the threaded mouth without spray paint to meet the requirements of some customers.

Maybe you will ask why there are semi-automatic line aluminum bottles and automatic line aluminum bottles? Yes, the types of bottles produced by the two different production lines will be different, that is, some products must be made by semi-automatic lines, such as essential oil bottles; while some are produced by automatic lines, such as beverage bottles. Of course, some products can be made by both production lines, but the MOQ will be different. For example, the aluminum threaded bottles we often use, the semi-automatic line MOQ is only 5000-10000, while the fully automatic line requires a minimum order of 30,000. Therefore, the specific production line to be used is determined by the products we need on the one hand, and on the other hand, it will be appropriately selected according to the customer's demand.

The above is some specific content introduction for aluminum bottles, I hope it will be helpful to you. If you have any questions about aluminum bottles, please contact us. We are a factory specializing in the production of aluminum bottles with rich industry experience. I hope we can help you with aluminum packaging.