Aluminum Bottle Leakage: A Common but Solvable Issue

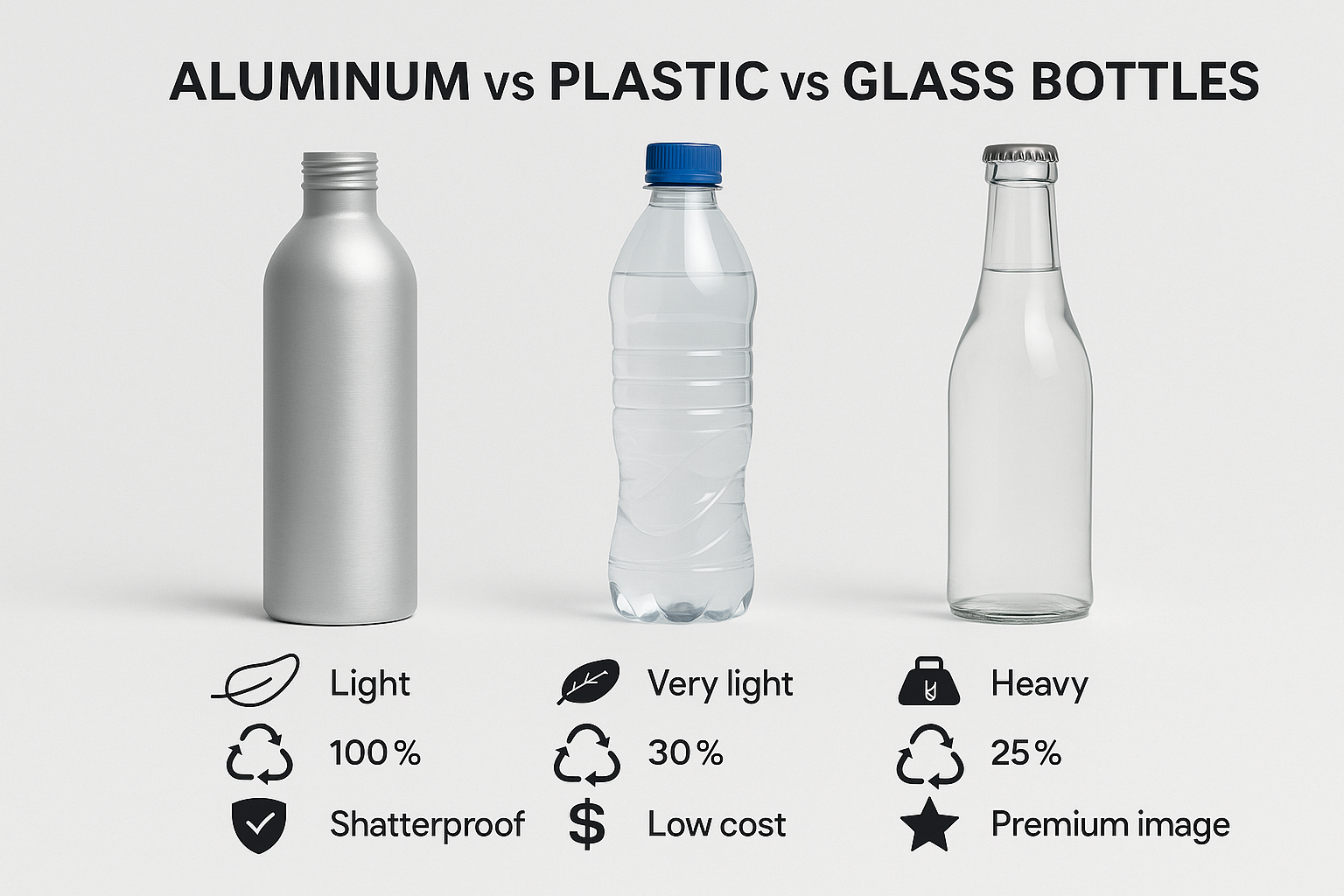

Aluminum bottles are a popular choice for packaging due to their durability, recyclability, and sleek appearance. However, one of the most common issues faced with aluminum packaging is leakage. This problem, while prevalent, is not insurmountable. Understanding the causes of leakage and implementing effective solutions can ensure the integrity of aluminum bottles.

Causes of Leakage in Aluminum Bottles

1. Chemical Reactions with Contents:

Issue: When the contents of an aluminum bottle are highly acidic or alkaline, they may react with the aluminum, leading to corrosion and leakage. This reaction can cause the contents to seep out or even spray from the bottle.

Solution: To prevent this, it's crucial to conduct compatibility tests between the contents and the aluminum packaging. Before recommending aluminum bottles to clients, always advise them to perform these tests. Providing samples for testing can ensure the safety and compatibility of the packaging material with the contents.

2. Active Contents:

Issue: Products that are highly effervescent, such as carbonated beverages, place additional pressure on the bottle and its seal. This can lead to leaks if the bottle is not properly sealed.

Solution: For products like sparkling water, suggestion to use ROPP cap. Or like other highly effervescent product, evaluating whether aluminum bottles are the best packaging choice is important. Inform clients about potential risks and recommend alternative packaging solutions to handle the pressure better.

3. Transport and Handling

Issue: During long-distance transport, the constant movement and handling of the bottles can cause leaks. The jostling and repeated handling can weaken the seal or cap, leading to leakage.

Solution: To mitigate this, consider using a combination sealing method. For example, use an aluminum screw cap for sealing the bottle during transport and provide the consumer with a functional cap like a spray nozzle or pump at the point of sale. Additionally, using an extra inner plug can enhance the seal and prevent leaks during transport.

Preventing Leakage: Effective Solutions

- Compatibility Testing: Always perform comprehensive compatibility testing between the contents and the aluminum bottle. This step is crucial, especially when using the packaging for the first time. Providing samples for testing ensures the product's safety and compatibility.

- Appropriate Packaging for Effervescent Products: When dealing with highly active contents, consider alternative packaging options. Educate clients about the potential risks of using aluminum bottles for such products and suggest safer alternatives.

- Enhanced Sealing Methods: Utilize combination sealing methods to ensure the integrity of the bottle during transport. Using an aluminum screw cap with an additional inner plug can provide extra security against leaks. At the point of sale, offer consumers a functional cap that meets their needs.

Conclusion

Aluminum bottle leakage is a common issue but can be effectively managed with the right strategies. By understanding the causes of leakage and implementing targeted solutions, you can ensure the integrity and reliability of aluminum packaging. Conducting compatibility tests, choosing appropriate packaging for different products, and using enhanced sealing methods are key steps in preventing leaks and maintaining the quality of your products.