Are you thinking about using 4 oz aluminum bottles for your product packaging? These small bottles probably change the game! They are very practical.

4 oz aluminum bottles serve many purposes and are eco-friendly packaging solutions. They work well for cosmetics, personal care products and food storage. These bottles provide excellent protection from leaks. This feature makes them a top choice for brands that value quality and care about the environment.

I explored aluminum packaging and found that 4 oz aluminum bottles are very versatile and sustainable. They suit a wide range of items, including cosmetics and food. I learned that these bottles prevent leaks effectively. This was important for my brand. Companies can customize them with logos and the bottles come with good seals. This discovery gave me peace of mind. They align with my environmental values. This really makes them an excellent option for brands like mine that prioritize quality.

4 oz aluminum bottles are suitable for food storage.True

These bottles provide excellent protection and are safe for storing food items, making them a versatile choice for packaging.

4 oz aluminum bottles are only for cosmetic products.False

While popular in cosmetics, these bottles are versatile and can be used in various applications beyond just cosmetics.

Why Should You Consider Custom Logo Printing on Aluminum Bottles?

A bottle sometimes tells your brand's story. Custom logos on aluminum bottles probably do this very well. These bottles give amazing advantages. Marketing efforts really rise with them.

Custom logo printing on aluminum bottles provides many advantages. It helps brands become more visible. People easily notice logos on bottles and this can really increase product awareness. Aluminum bottles also offer excellent product quality. Many products fit well in these bottles. This packaging choice appeals to eco-friendly consumers. It is a sustainable option. Using this method truly enhances brand image. This marketing strategy is impactful.

Enhance Brand Visibility

Custom logo printing on aluminum bottles does more than look nice; it builds a bond with people. I recall when I started branding my laundry detergent. I needed something unique that would resonate with customers. That’s when I saw how powerful aluminum bottles could be. They are not just containers - they are canvases for my brand's personality!

Imagine being at an outdoor event among lively stalls and eager people. As I handed out my custom aluminum bottles, I noticed their eyes sparkled with interest. Logos on everyday products become part of people's lives. Logos remind them of your brand constantly. These bottles do not vanish after the event. They travel everywhere, shared and reused, always extending your brand's presence.

Quality and Durability

Choosing packaging that keeps my product safe was very important to me. Aluminum bottles are lightweight but very strong. Correct inner coatings keep contents fresh and free from harm. This is very crucial, especially when customers rely on you for their laundry needs. Initially, I feared leaks, but aluminum bottles removed that worry entirely. My logo now gleams on bottles that last, just like my promise of quality.

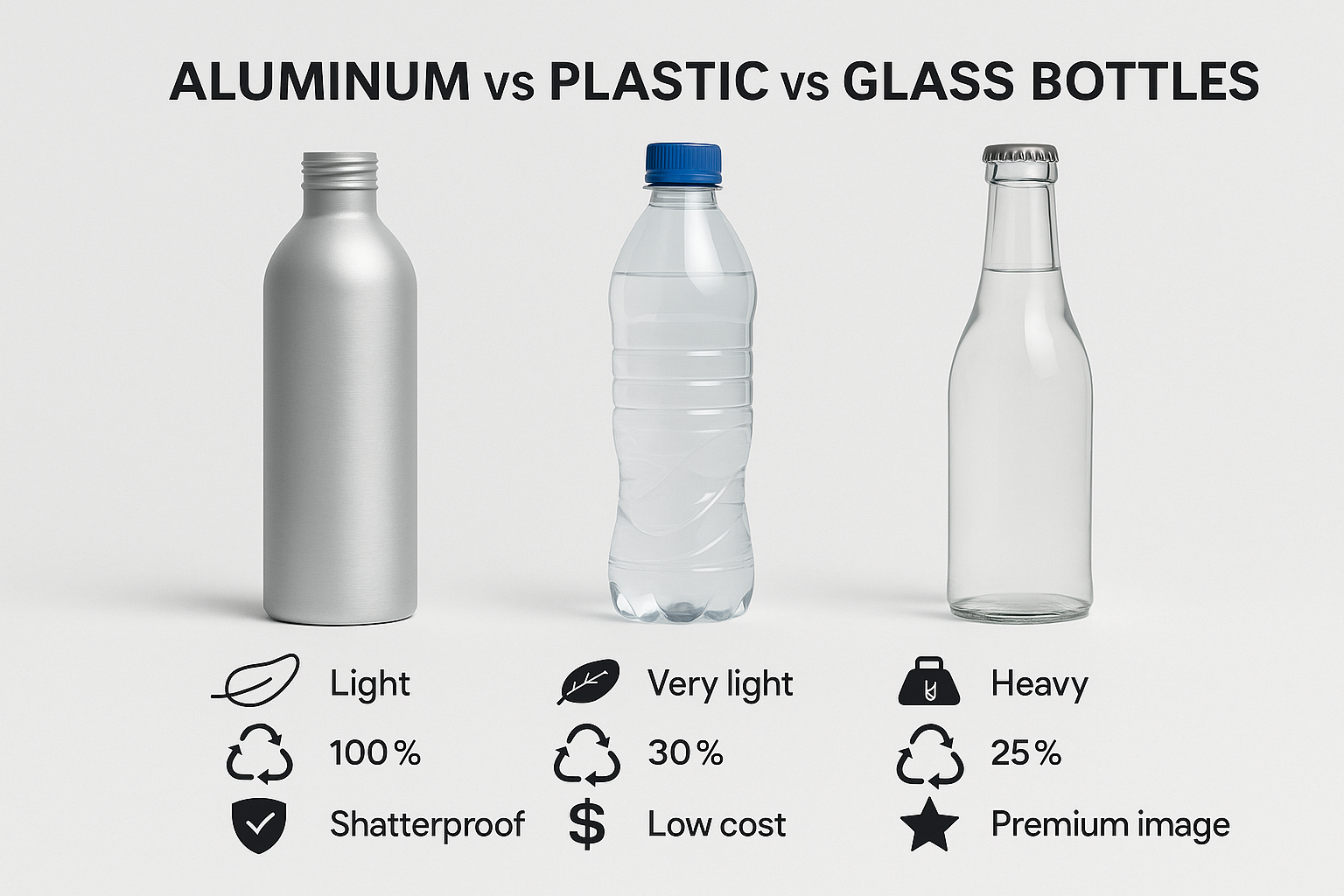

A table comparing the durability of aluminum with other materials might illustrate this point effectively:

| Material | Durability | Environmental Impact | Cost Effectiveness |

|---|---|---|---|

| Aluminum | High | Low | Moderate |

| Plastic | Moderate | High | Low |

| Glass | Low | Moderate | High |

Versatile Applications

Aluminum bottles offer many uses. They suit everything from personal care goods to drinks. Customizing these bottles for different times and events adds a special touch. For instance, special edition bottles can be created for holidays or launches, maximizing their promotional potential.

I remember launching a holiday edition detergent in bright colors - nobody could resist it! Such creativity keeps customers curious about what comes next.

Sustainable Choice

Nowadays, being eco-friendly is essential, not just a trend. By picking aluminum bottles, I feel like I contribute to the planet’s well-being. They recycle easily and keep their quality, which I proudly share with customers through custom printed logos that reflect eco-friendliness.

This approach not only boosts brand image but also appeals to environmentally-conscious consumers looking for sustainable options in packaging.

Summary of Benefits

In conclusion, custom logo printing on aluminum bottles provides numerous perks:

- Increased Brand Visibility: Your logo enjoys frequent attention.

- Durability and Quality: Leaves a lasting impression of your brand.

- Versatile Applications: Suitable for a vast range of products and events.

- Sustainability: Matches eco-friendly practices.

Using these ideas in our marketing plan, I’ve smartly used custom logo printing on aluminum bottles to gain an edge in the market. It’s surprising how a simple bottle can really create connections and lift my brand to great heights!

Custom logo printing increases brand exposure at events.True

When aluminum bottles with logos are used at events, they create ongoing visibility for the brand, enhancing recognition among attendees.

Aluminum bottles are less durable than plastic bottles.False

Aluminum bottles are known for their high durability compared to plastic, making them a better choice for maintaining product integrity.

How Does Inner Coating Affect Product Quality and Shelf Life?

Has anyone ever thought about how the inside layers of aluminum containers change the quality and shelf life of what's inside? Let’s explore this interesting topic and find out how these layers do their wonderful job.

Coatings inside containers are essential for keeping products fresh. They stop reactions with aluminum. Spoilage is greatly reduced by these coatings. Flavor stays original and good. Look into different kinds of coatings and their advantages. This knowledge will improve your packaging methods.

Understanding Inner Coatings

I remember the first time I held one of our aluminum bottles. It felt very sturdy and lightweight. I realized these bottles were not only containers; they were like guardians of the products inside. When I think of my laundry detergent brand, the inner coating has a crucial role. It protects the quality and shelf life of my products. It's like a protective hug that keeps the detergent fresh for my customers—very fresh and effective.

Inner coatings are essential for enhancing the quality and shelf life of products stored in aluminum containers. They act as a protective barrier between the product and the container, preventing reactions that could compromise quality. For example, in food and beverages, coatings can prevent metal leaching and protect flavors.

Types of Inner Coatings

I’ve found that there are several types of inner coatings, each serving different purposes:

| Coating Type | Description | Applications |

|---|---|---|

| Epoxy | Durable and resistant to chemicals, ideal for beverages | Soft drinks, juices |

| Polyethylene | Provides moisture barrier properties | Personal care products |

| Polypropylene | Offers flexibility and resistance to heat | Food products |

Impact on Product Quality

From my journey, I know how crucial an inner coating is for maintaining product quality. Without it, chemical reactions between aluminum and the product occur. This can lead to bad flavors or spoilage. For acidic products like fruit juices, the aluminum might corrode, changing taste and safety. It's a tough reality—but with the right coatings, we avoid these problems.

The presence of an inner coating significantly affects product quality. Without it, chemical reactions between the aluminum and the product can lead to off-flavors or spoilage.

Extending Shelf Life

Using appropriate inner coatings is like having a secret weapon to extend shelf life. These coatings inhibit microbial growth and oxidation—two major factors contributing to spoilage. Edible coatings fascinate me; they help preserve dairy products by stopping moisture loss. It's amazing how much longer products last with wise choices—very wise.

By using appropriate inner coatings, manufacturers can effectively extend shelf life. These coatings inhibit microbial growth and oxidation, two major factors contributing to spoilage. For example, edible coatings1 can enhance preservation in dairy products by forming a barrier against moisture loss.

Environmental Considerations

I value environmental protection deeply; many modern inner coatings are eco-friendly options designed to reduce our ecological footprint while keeping product integrity intact—a win-win situation! I often research sustainable packaging solutions (sustainable packaging solutions2) to meet the demand for green products because maybe every small step really counts.

In line with Matt’s commitment to environmental protection, many modern inner coatings are designed to be eco-friendly options that help reduce ecological footprints while maintaining product integrity.

Innovations in Inner Coatings

I’m very excited about new advancements in coating technologies that make barriers more effective! Companies are exploring smart coatings3 that change properties based on environmental conditions—providing dynamic protection for sensitive products! It's thrilling to imagine future possibilities as we continually improve our packaging solutions.

Inner coatings prevent metal leaching in aluminum containers.True

Inner coatings act as a barrier, preventing reactions that can cause metal leaching, thus maintaining product safety and quality.

All inner coatings are environmentally harmful to products.False

Not all inner coatings are harmful; many modern options are eco-friendly and designed to reduce ecological impact while preserving product integrity.

What Are the Different Sealing Types for Aluminum Bottles?

I value quality and sustainability in packaging. Picking the correct seal for aluminum bottles is very important. It's not just a technical decision. It really keeps the product safe. It also makes customers happy.

You have different ways to seal aluminum bottles. Induction sealing, pressure-sensitive liners, snap-on caps and twist-off caps are among your options. Each option offers its own unique benefits. These methods keep the product's quality intact. They also stop leaks very effectively.

When it comes to packaging products in aluminum bottles, understanding the different sealing types is crucial for ensuring product integrity and preventing leakage. Each sealing method has its unique advantages, making them suitable for various applications.

Induction Sealing

Induction sealing caught my attention. This process uses electromagnetic waves to create a tight seal. It heats a foil liner, so it sticks to the bottle's mouth. I remember the first time I saw it working. There’s something reassuring about that pop when opening a bottle. It means the seal is tight. The benefits include:

- Great barrier properties

- Tamper-evident features boost customer trust

- Works with many products, from cosmetics to medicines

Learn more about how induction sealing can improve your product’s shelf life and safety by looking into induction sealing processes4.

Pressure-Sensitive Liners

Pressure-sensitive liners became a favorite of mine. They seal easily but stop leaks very well. They remind me of my first time opening a laundry detergent bottle. I could access the product without any spills. Here are key points:

- Quick application saves time

- Cost-effective, which is a plus for any business

- Options for reuse and recycling, matching my love for environmental care

Discover more about the advantages of pressure-sensitive liners5 and how they can fit into your packaging plan.

Snap-On Caps

Now, let's talk about snap-on caps. They work perfectly with aluminum bottles. I think of snap-on caps and see the ease they offer - just snap and go! They’re really great for:

- Beverages consumed quickly

- Personal care items needing frequent opening

- Daily household items

If improving your product lineup interests you, check out the benefits of using snap-on caps6.

Twist-Off Caps

Twist-off caps excel for those who value ease of use and freshness. The first time I saw twist-off caps, I liked their secure fit and resealing ability. It’s like giving extra convenience to customers. Some advantages are:

- No spills during transport due to a secure closure

- Resealable for freshness later

- Suitable for many liquids, making them highly versatile

For further information about twist-off cap features7 and uses, delve into this topic.

Table of Sealing Methods Comparison

| Sealing Type | Advantages | Best For |

|---|---|---|

| Induction Sealing | Excellent barrier properties, tamper-evident | Pharmaceuticals, cosmetics |

| Pressure-Sensitive | Quick application process, cost-effective | Food products, cleaners |

| Snap-On Caps | Simple yet effective solution | Beverages, personal care items |

| Twist-Off Caps | Secure closure with resealability | Liquids |

By discovering these sealing types, I chose wisely how to package my products. I tackled worries like leakage and product safety. It’s about creating a customer experience that shows quality and reliability. That’s what all of us strive for in our businesses.

Induction sealing provides a hermetic seal for aluminum bottles.True

Induction sealing creates a hermetic seal, ensuring product integrity and preventing leakage, making it ideal for sensitive products like pharmaceuticals and cosmetics.

Snap-on caps are not suitable for beverages.False

Snap-on caps are commonly used for beverages due to their simple application and effective sealing capabilities, ensuring no leaks occur during use.

What Are the Best Uses for 4 Oz Aluminum Bottles?

Ever found a bottle that works perfectly everywhere in your life? I really have! Aluminum bottles of 4 oz are practical. They are also very versatile. These bottles are a favorite choice in many industries. Let’s explore their interesting uses together!

4 oz aluminum bottles find use in cosmetics, food and drink packaging and medicine. Their flexibility comes from options that can be customized. These bottles have special coatings inside to keep products fresh. Different sealing methods make brands stand out and keep quality high. Quality is very important.

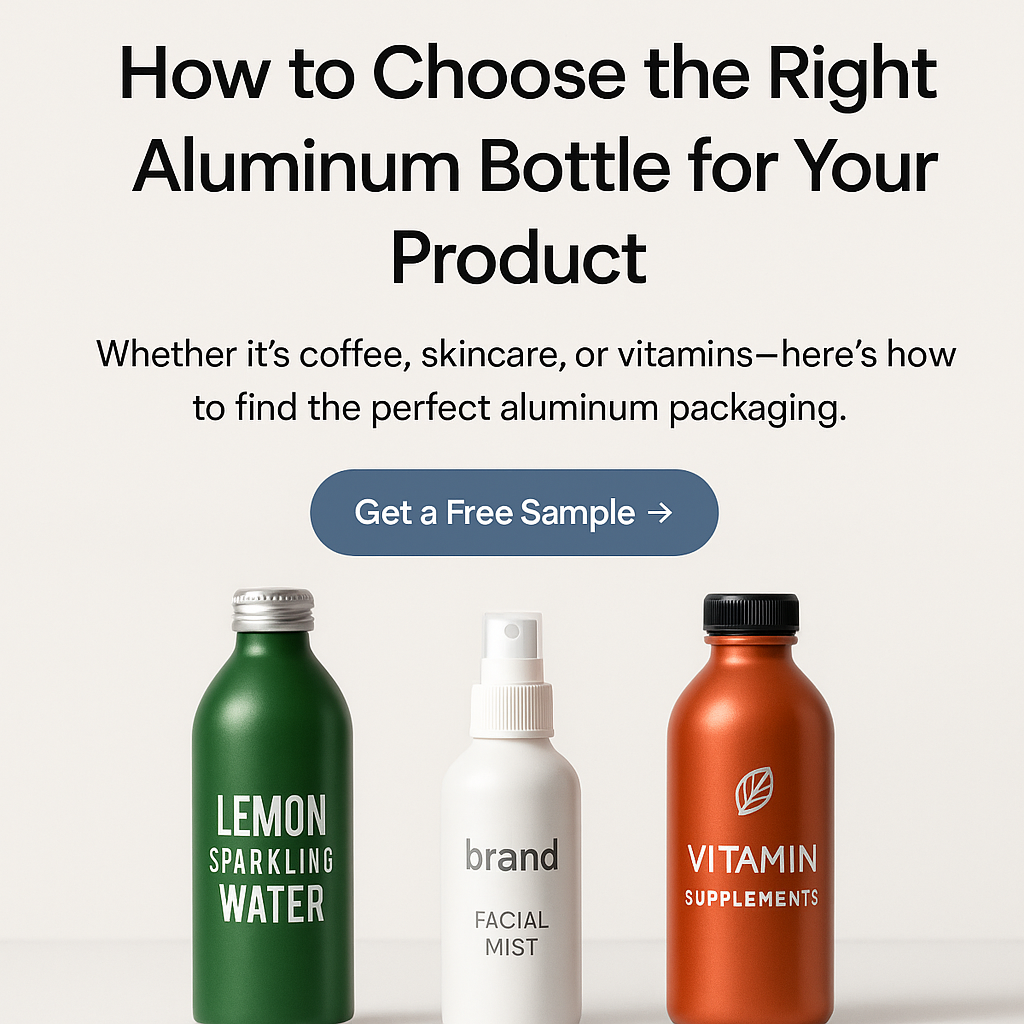

Custom Logo Printing

One of the standout features of 4 oz aluminum bottles is their ability to be customized with logo printing. This allows brands to enhance their visibility and build a strong brand identity.

Many companies in various sectors, such as cosmetics and beverages, utilize custom logo printing to create a unique packaging experience. For instance, a laundry detergent brand can showcase its logo prominently, thus reinforcing its presence in consumers' minds. This not only aids in brand recognition but also adds an element of professionalism and trustworthiness to the product.

Moreover, custom printing can cater to seasonal promotions or limited editions, allowing businesses to attract attention in a crowded market. Explore more about custom branding options8.

Inner Coating

The inner coating of aluminum bottles plays a crucial role in preserving product quality. Depending on the contents, different types of coatings can be applied to prevent reactions between the aluminum and the product inside.

For instance, personal care products often require specific coatings to ensure the stability and safety of ingredients. This feature is particularly important for sensitive formulas that can deteriorate when exposed to aluminum. A well-chosen inner coating can significantly extend shelf life, making 4 oz aluminum bottles suitable for products such as:

| Product Type | Recommended Coating |

|---|---|

| Hair Care Products | Epoxy-phenolic Coating |

| Essential Oils | Food-Grade Coating |

| Beverages | Non-Toxic Polyethylene |

Thus, understanding the appropriate inner coating for your product can make a significant difference in its effectiveness. Learn about inner coatings.

Sealing Types

Different sealing types ensure that 4 oz aluminum bottles maintain their integrity during transportation and storage. The choice of sealing method depends on the product's nature and usage.

Here are some common sealing types used in aluminum bottles:

| Sealing Type | Description | Ideal For |

|---|---|---|

| Screw Caps | Provide tight sealing; easy to open | Liquids and creams |

| Flip Tops | Convenient for quick dispensing | Personal care products |

| Child-Resistant Caps | Designed to prevent access by children | Pharmaceuticals |

Selecting the right sealing type is essential for preventing leaks and ensuring customer satisfaction. Discover sealing options.

Applications Across Various Sectors

4 oz aluminum bottles find applications across diverse sectors due to their versatility and eco-friendliness. Here are some notable applications:

- Cosmetics: Perfect for lotions, serums, and other skincare products.

- Food & Beverage: Ideal for sauces, oils, or craft beverages, ensuring freshness and taste retention.

- Pharmaceuticals: Suitable for essential oils and other medicinal liquids requiring secure packaging.

These applications highlight the adaptability of 4 oz aluminum bottles, proving their worth in multiple industries. Check out applications in detail.

4 oz aluminum bottles can be customized with logos.True

Custom logo printing on 4 oz aluminum bottles enhances brand visibility and identity, making them effective for various industries.

Inner coatings are unnecessary for aluminum bottles.False

Inner coatings are essential for preserving product quality in aluminum bottles, preventing reactions between the aluminum and contents.

Conclusion

Explore the benefits of 4 oz aluminum bottles for packaging, including customization options, inner coatings for quality preservation, various sealing types, and diverse applications across industries.

-

Discover how inner coatings can improve your product's longevity and safety, ensuring better quality over time. ↩

-

Learn about different types of inner coatings and their applications across various industries. ↩

-

Find out about eco-friendly coating options that align with sustainable practices in packaging. ↩

-

Discover the various sealing methods available for aluminum bottles to choose the best one for your packaging needs. ↩

-

Learn how pressure-sensitive liners work and why they might be ideal for your products. ↩

-

Understand the advantages of snap-on caps and how they can be applied to your products. ↩

-

Explore twist-off caps and their functionality in packaging applications. ↩

-

Discover how various industries utilize aluminum bottles effectively for their products. This will help you understand their versatility and potential benefits. ↩